-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

I. Introduction

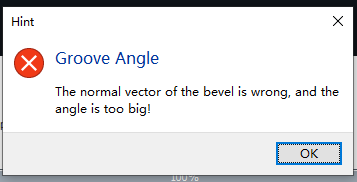

[Normal Vector Error Detection] automatically detects toolpaths with obvious errors in the direction of normal vectors, and provides intuitive pop-ups and markers to help quickly identify problematic vectors and avoid machining with incorrect vectors.

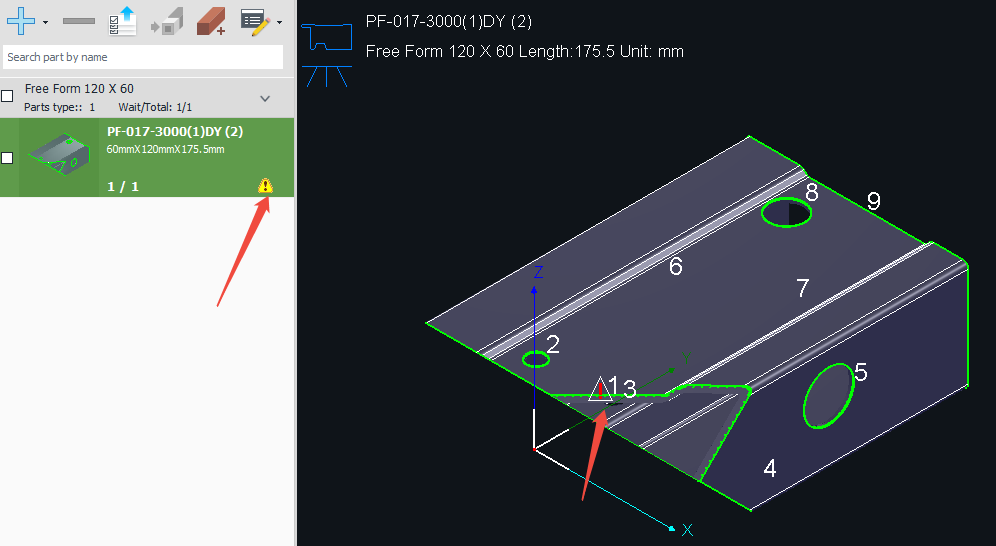

For safety reasons, a pop-up window will appear when a bevel toolpath with abnormal vectors is detected.

At the same time, there is also a corresponding “small triangle exclamation mark” in the software, which can locate ① the parts in the parts list; ② a specific toolpath problem. Mouse over the “small triangle exclamation point”, there will be a specific cause of the tool path vector error.

Note: Italic texts with blue highlights are clickable tutorial links that lead to detailed parameter explanations and usage instructions.

II. How to Use

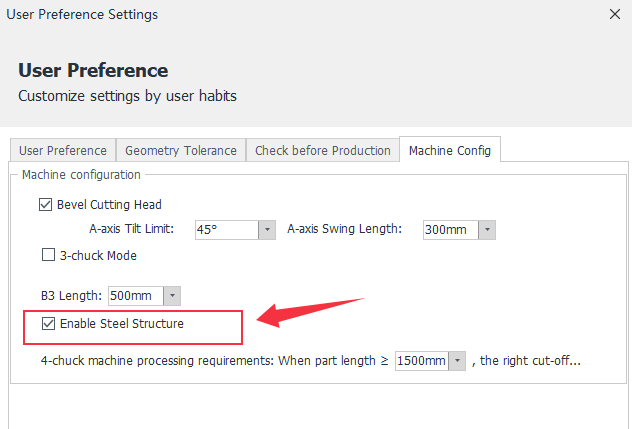

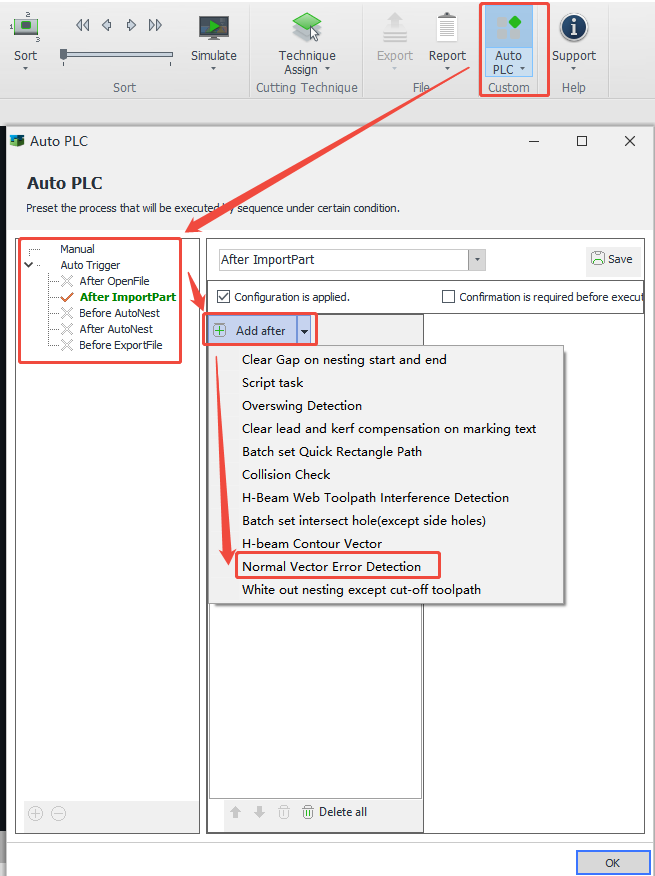

1. Click the software's [Auto PLC] function.

Note: To use the [Auto PLC] function, you need to obtain the steel structure robtain the steel structure package, and then in the <User Preference> → <Machine Configuration>, check the box “Enable Steel Structure”.

2. Select a certain trigger time, click <After ImportPart>, and find [Normal Vector Error Detection].

Note: After turning on [Auto Process], the software will configure the [Normal Vector Error Detection] function by default in <After Importing Part> and <Before AutoNest>.

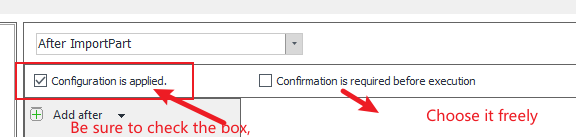

3. Check <Configuration takes effect> and click <OK>.

Ⅲ. FAQS

1、After the pop-up window appears, what should be the next step?

If prompted “Error Normal Vector in toolpath” (i.e. "零件刀路存在错误法向量"):

① If the part is a closed cross-section (such as square tube or round tube, etc.), then in the parts list check the prompted parts, click [Cancel Bevel], and then click [Scan Bevel], you can batch re-recognition.

② If the scanning of the bevel still fails, you can click the <Display Normal Vector>, check the knife path with a “small triangle exclamation point”, check which place vector is not correct.

③ After finding the place with abnormal vectors, observe that the drawing here is drawn correctly.

If the drawing is abnormal, modify the drawing; if the drawing is correct, ask the group leader in the community.

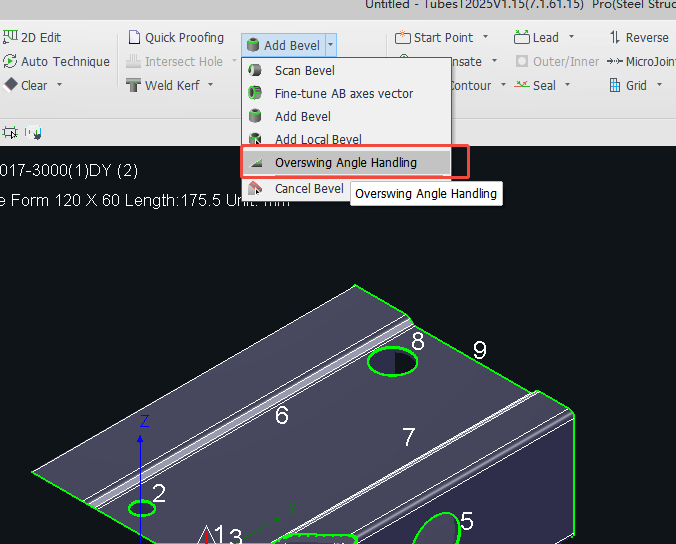

If prompted “overswing exsits in part toolpath” (i.e. "零件刀路存在超摆角"):

use the [Overswing Angle handling] function to deal with the part.

2、For the bevel toolpath, [Normal Vector Error Detection] through, still need to carry out the [Vector Modify]-[Auto Modify]?

Yes. For beveled toolpath, it is recommended to use [Normal Vector Error Detection] function, but must use [Vector Modify] function.

[Normal Vector Error Detection] function does not carry the cutting head model information, i.e., it does not take into account the effect of the size of the cutting head on part interference. This function makes it easy for users who need to cut bevels but do not have a ses cutting head model to detect abnormal vectors on the part before machining.

The [Auto Collision Avoidance] function, on the other hand, performs interference detection on the swing angle based on the volume of the cutting head, and automatically modifies the angle at which a collision may occur to a safe position.

IV. Video Tutorial

I. Introduction

[Normal Vector Error Detection] automatically detects toolpaths with obvious errors in the direction of normal vectors, and provides intuitive pop-ups and markers to help quickly identify problematic vectors and avoid machining with incorrect vectors.

For safety reasons, a pop-up window will appear when a bevel toolpath with abnormal vectors is detected.

At the same time, there is also a corresponding “small triangle exclamation mark” in the software, which can locate ① the parts in the parts list; ② a specific toolpath problem. Mouse over the “small triangle exclamation point”, there will be a specific cause of the tool path vector error.

Note: Italic texts with blue highlights are clickable tutorial links that lead to detailed parameter explanations and usage instructions.

II. How to Use

1. Click the software's [Auto PLC] function.

Note: To use the [Auto PLC] function, you need to obtain the steel structure robtain the steel structure package, and then in the <User Preference> → <Machine Configuration>, check the box “Enable Steel Structure”.

2. Select a certain trigger time, click <After ImportPart>, and find [Normal Vector Error Detection].

Note: After turning on [Auto Process], the software will configure the [Normal Vector Error Detection] function by default in <After Importing Part> and <Before AutoNest>.

3. Check <Configuration takes effect> and click <OK>.

Ⅲ. FAQS

1、After the pop-up window appears, what should be the next step?

If prompted “Error Normal Vector in toolpath” (i.e. "零件刀路存在错误法向量"):

① If the part is a closed cross-section (such as square tube or round tube, etc.), then in the parts list check the prompted parts, click [Cancel Bevel], and then click [Scan Bevel], you can batch re-recognition.

② If the scanning of the bevel still fails, you can click the <Display Normal Vector>, check the knife path with a “small triangle exclamation point”, check which place vector is not correct.

③ After finding the place with abnormal vectors, observe that the drawing here is drawn correctly.

If the drawing is abnormal, modify the drawing; if the drawing is correct, ask the group leader in the community.

If prompted “overswing exsits in part toolpath” (i.e. "零件刀路存在超摆角"):

use the [Overswing Angle handling] function to deal with the part.

2、For the bevel toolpath, [Normal Vector Error Detection] through, still need to carry out the [Vector Modify]-[Auto Modify]?

Yes. For beveled toolpath, it is recommended to use [Normal Vector Error Detection] function, but must use [Vector Modify] function.

[Normal Vector Error Detection] function does not carry the cutting head model information, i.e., it does not take into account the effect of the size of the cutting head on part interference. This function makes it easy for users who need to cut bevels but do not have a ses cutting head model to detect abnormal vectors on the part before machining.

The [Auto Collision Avoidance] function, on the other hand, performs interference detection on the swing angle based on the volume of the cutting head, and automatically modifies the angle at which a collision may occur to a safe position.

IV. Video Tutorial