-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

I. Introduction

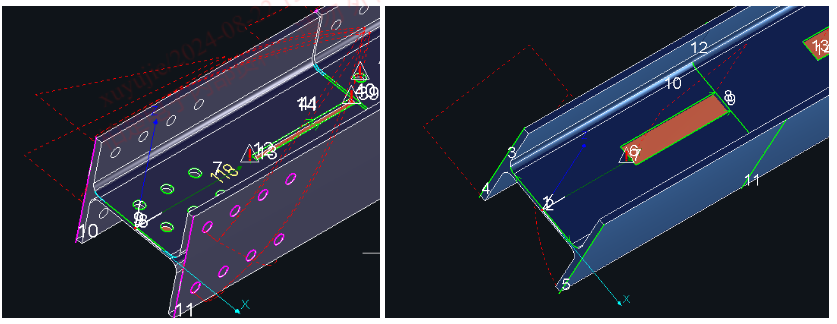

When cutting the flange with FACut-H, the cutting head emits the laser horizontally, causing slag to fall onto the web. The slag splashes in a fan shape, covering a certain area in the Y direction depending on the cutting process.

If the web is cut immediately afterward, the accumulated slag may frequently scrape the nozzle, making it impossible for stable production.

To solve this issue, TubesT introduced Slag-free Sort.

II. How to Use

1. Permission related

① This function is exclusive to the TubesT-H, and the TubesT does not have it.

② Please use with FACut-H 2.2.2404.5 or higher. *Exclusive to FACut-H (not available for TubePro).

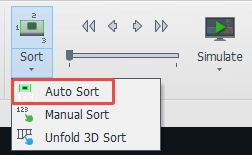

2. function position

-

- Sort → Auto Sort → Sort by Face

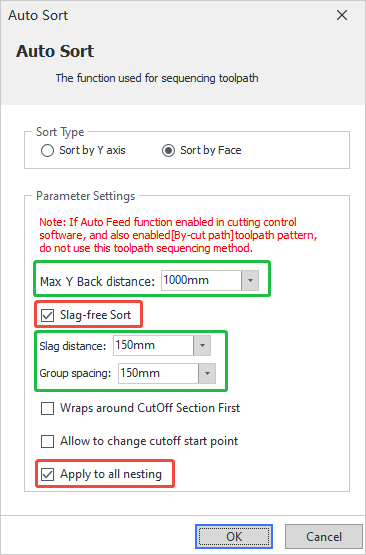

3. Recommended parameters

-

- Please check < Slag-free Sort> and <Apply to all Nesting>.

- Keep default values for other parameters:

-

-

- Max Y Back distance: 1000 mm

- Slag distance: 150 mm

- Group spacing: 150 mm

-

4. Note

Use it as the last step before exporting!

*Modifying toolpaths (e.g., adding wrapping lines, manual sorting) after using this feature will trigger a warning saying "Slag-free sorting is invalid now. Please check the current toolpath sorting!"

III. More About the Feature

- What is Max Y Back distance?

-

If Max Y Back distance is not set, the machine may first complete all web cutting, then return to the starting position to cut the first flange toolpath, resulting in long idle movements.

-

Additionally, when cutting reaches the end of the material, operators may assume the process is nearly finished and move closer, increasing the risk of collisions when the machine retracts.

-

Setting this parameter ensures that within this distance, factors such as hole grouping, slag prevention, and shortest travel are considered, keeping the Y-axis retraction within the set value.

-

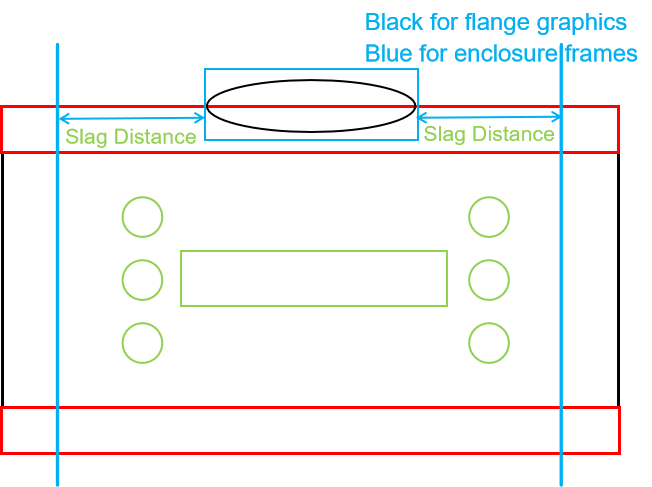

- What is Slag distance?

-

The system extends a Slag distance on the front and rear sides along the Y-axis of the flange toolpath (excluding marking lines).

-

Web plate toolpaths within this range are processed first before cutting the flange.

-

- What is Group spacing?

-

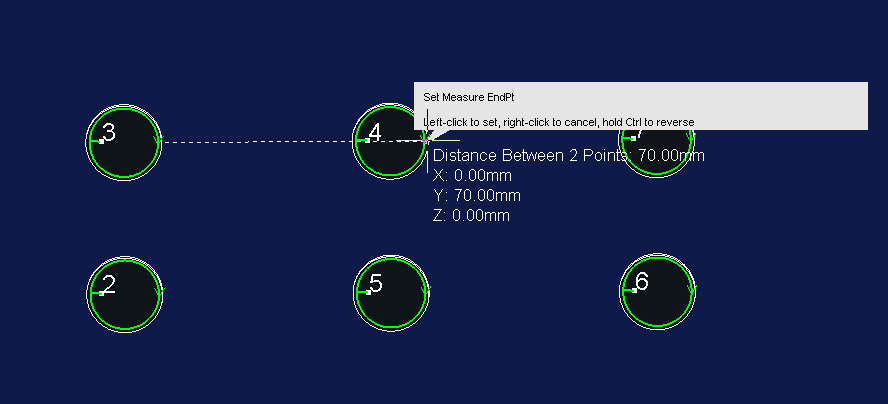

Holes within 150 mm of each other are grouped together.

-

For example, if holes are 70 mm apart, they are considered a single group and cut together to optimize the sorting process.

-

Ⅳ. Q&A

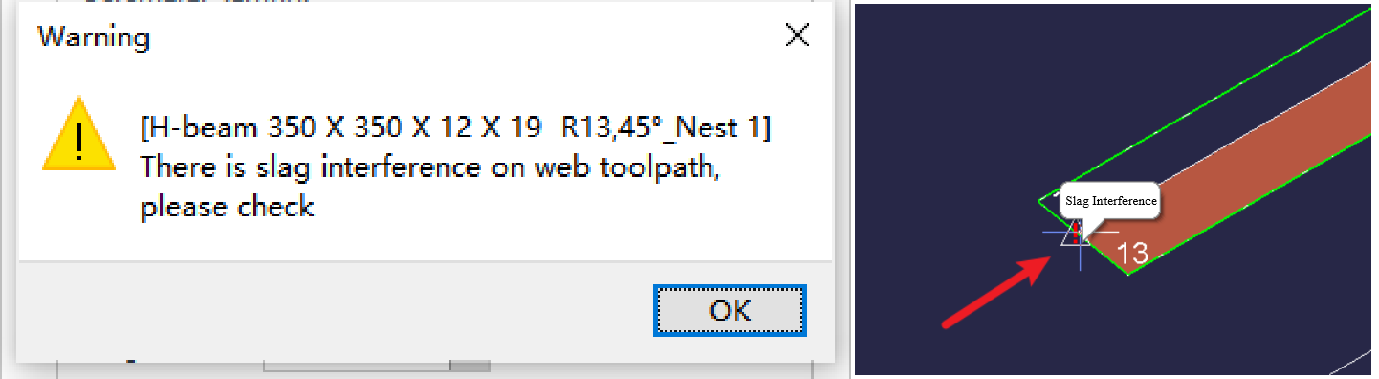

1. What if I get a warning like the one shown below after using the 【Slag-free Sort】?

-

- As mentioned in the prompts, this means that there is a slag interference on web toolpath. You will see the “small triangle + exclamation point” in the figure, and the specific reason will be displayed when you mouse over it.

- If the number of results affected by the slag is not much, and it can be accepted in the cutting of the web when some slag will exist, then you can ignore the warning. Click OK to continue (recommended to continue directly).

- If the actual cutting is seriously affected by the slag spray, you can adjust the above parameters. Check if the Slag distance is too large. If not, check whether the Group spacing can be smaller. Otherwise, increase the Max Y Back distance.

2. What does it mean when a red line alert appears?

-

- Indicates the toolpath exceeds the Max Y Back distance (safety alert).

- If considering the various requirements, and decided to accept that individual position may exceeds the Max Y Back distance, you can directly export the results for processing. FACut-H will also prompt the red line, so the operator should pay attention to the safety.

- If multiple red lines appear, check if the Slag distance and Grouping spacing settings are reasonable.

I. Introduction

When cutting the flange with FACut-H, the cutting head emits the laser horizontally, causing slag to fall onto the web. The slag splashes in a fan shape, covering a certain area in the Y direction depending on the cutting process.

If the web is cut immediately afterward, the accumulated slag may frequently scrape the nozzle, making it impossible for stable production.

To solve this issue, TubesT introduced Slag-free Sort.

II. How to Use

1. Permission related

① This function is exclusive to the TubesT-H, and the TubesT does not have it.

② Please use with FACut-H 2.2.2404.5 or higher. *Exclusive to FACut-H (not available for TubePro).

2. function position

-

- Sort → Auto Sort → Sort by Face

3. Recommended parameters

-

- Please check < Slag-free Sort> and <Apply to all Nesting>.

- Keep default values for other parameters:

-

-

- Max Y Back distance: 1000 mm

- Slag distance: 150 mm

- Group spacing: 150 mm

-

4. Note

Use it as the last step before exporting!

*Modifying toolpaths (e.g., adding wrapping lines, manual sorting) after using this feature will trigger a warning saying "Slag-free sorting is invalid now. Please check the current toolpath sorting!"

III. More About the Feature

- What is Max Y Back distance?

-

If Max Y Back distance is not set, the machine may first complete all web cutting, then return to the starting position to cut the first flange toolpath, resulting in long idle movements.

-

Additionally, when cutting reaches the end of the material, operators may assume the process is nearly finished and move closer, increasing the risk of collisions when the machine retracts.

-

Setting this parameter ensures that within this distance, factors such as hole grouping, slag prevention, and shortest travel are considered, keeping the Y-axis retraction within the set value.

-

- What is Slag distance?

-

The system extends a Slag distance on the front and rear sides along the Y-axis of the flange toolpath (excluding marking lines).

-

Web plate toolpaths within this range are processed first before cutting the flange.

-

- What is Group spacing?

-

Holes within 150 mm of each other are grouped together.

-

For example, if holes are 70 mm apart, they are considered a single group and cut together to optimize the sorting process.

-

Ⅳ. Q&A

1. What if I get a warning like the one shown below after using the 【Slag-free Sort】?

-

- As mentioned in the prompts, this means that there is a slag interference on web toolpath. You will see the “small triangle + exclamation point” in the figure, and the specific reason will be displayed when you mouse over it.

- If the number of results affected by the slag is not much, and it can be accepted in the cutting of the web when some slag will exist, then you can ignore the warning. Click OK to continue (recommended to continue directly).

- If the actual cutting is seriously affected by the slag spray, you can adjust the above parameters. Check if the Slag distance is too large. If not, check whether the Group spacing can be smaller. Otherwise, increase the Max Y Back distance.

2. What does it mean when a red line alert appears?

-

- Indicates the toolpath exceeds the Max Y Back distance (safety alert).

- If considering the various requirements, and decided to accept that individual position may exceeds the Max Y Back distance, you can directly export the results for processing. FACut-H will also prompt the red line, so the operator should pay attention to the safety.

- If multiple red lines appear, check if the Slag distance and Grouping spacing settings are reasonable.