-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

Ⅰ. How can Kerf Compensation(fixed height) help you?

Currently, fixed height cutting is widely used for toolpaths near the flanges of H-beams, such as scallops and tongues.

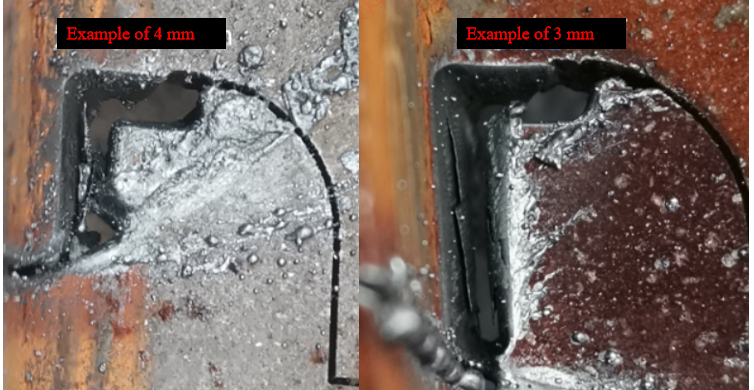

During production, it is found that the kerf of fixed-height cutting is wider than that of follow cutting. The kerf of fixed-height cutting is usually around 8 mm, while that of follow-cutting is usually around 1 mm.

If Kerf Compensation(fixed height) cutting is not adopted, there will be obvious gaps in the cutting tool path. Or, due to the large kerf of fixed-height cutting, the cutting head may plunge when cutting with a follow-up toolpath, as shown in the figure below.

Ⅱ. How to use

Prerequisite: The front root shall be set to zero in Optimize H-beam Web Toolpath of TubesT. And the Scallop Calibration Value in FACut-H shall be set to zero as well.

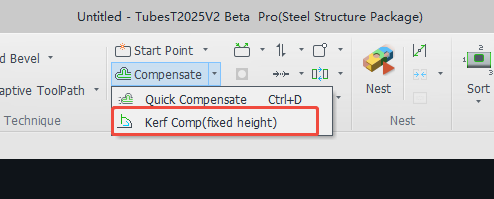

① Click on the drop-down menu of Compensate, and select Kerf Comp(fixed height).

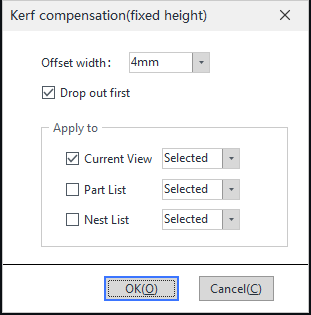

② For the value of Offset width, 4 mm is recommended for hot-rolled H-beam, which can be adjusted later in FACut-H. After the applied scope has been set, the Kerf Comp(fixed height) will be added to toolpaths within the selected scope.

-

-

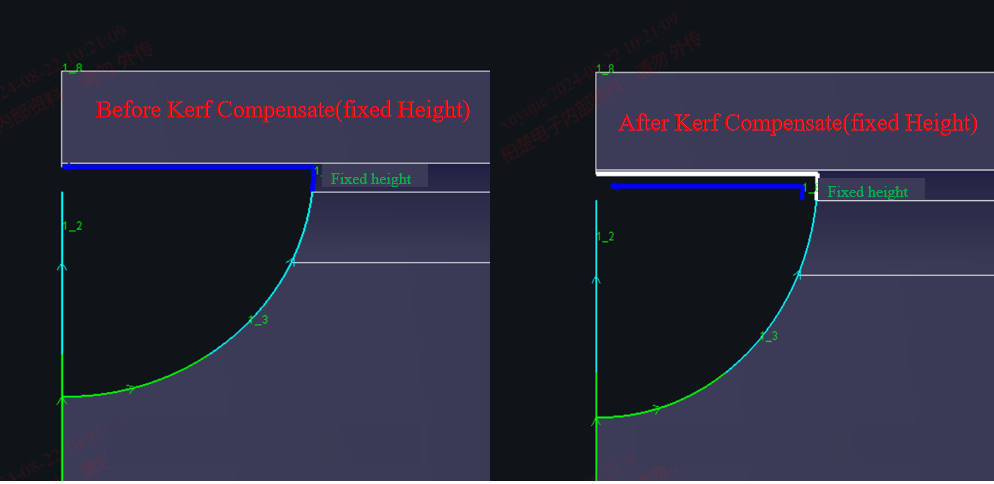

- The contrast is shown below:

-

Ⅲ. Functionality

- Parameters

1. Kerf Compensate: To compensate for dimensional deviations caused by kerf width during height-fixed cutting, the cutting path position is adjusted through compensation, ensuring the actual cutting trajectory meets processing requirements.

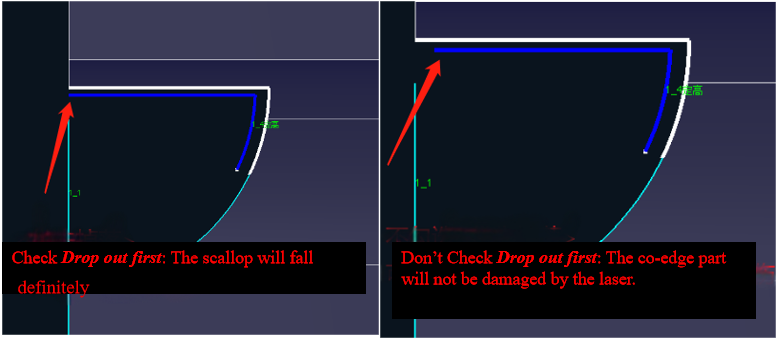

2. Drop out first (newly added in TubesT 7.1.57.19): This setting offers two cutting strategies for scallops:

-

-

-

Checked: Ensures definite drop-off.

-

Unchecked: Ensures parts are not damaged.

-

-

3. Apply to: You can apply Kerf Comp(fixed height) to the parts of the Current View, Part List, or Nest List.

Ⅳ. FAQS

1. How to cancel Kerf Compensate(fixed height)?

Click on the drop-down menu of Clear, and select Clear Kerf Comp(fixed height).

2. How the direction of Kerf Comp(fixed height) is determined?

The direction is determined automatically based on the position of wasted materials and the parts. However, if the direction is not what you prefer, you can send your feedback.

3. After setting the Kerf Comp(fixed height) parameters in TubesT, if it's found to be too large or too small during actual cutting, how to modify ?

It can be directly modified in FACut-H.

4. If ordinary compensation is set for parts with fixed height tool paths, whether it will take effect?

If the ordinary compensation is set for the part with a fixed-height toolpath, then the compensation will not be effective for the fixed-height toolpath. Namely, the fixed-height toolpath can only be set with the fixed-height compensation.

Ⅰ. How can Kerf Compensation(fixed height) help you?

Currently, fixed height cutting is widely used for toolpaths near the flanges of H-beams, such as scallops and tongues.

During production, it is found that the kerf of fixed-height cutting is wider than that of follow cutting. The kerf of fixed-height cutting is usually around 8 mm, while that of follow-cutting is usually around 1 mm.

If Kerf Compensation(fixed height) cutting is not adopted, there will be obvious gaps in the cutting tool path. Or, due to the large kerf of fixed-height cutting, the cutting head may plunge when cutting with a follow-up toolpath, as shown in the figure below.

Ⅱ. How to use

Prerequisite: The front root shall be set to zero in Optimize H-beam Web Toolpath of TubesT. And the Scallop Calibration Value in FACut-H shall be set to zero as well.

① Click on the drop-down menu of Compensate, and select Kerf Comp(fixed height).

② For the value of Offset width, 4 mm is recommended for hot-rolled H-beam, which can be adjusted later in FACut-H. After the applied scope has been set, the Kerf Comp(fixed height) will be added to toolpaths within the selected scope.

-

-

- The contrast is shown below:

-

Ⅲ. Functionality

- Parameters

1. Kerf Compensate: To compensate for dimensional deviations caused by kerf width during height-fixed cutting, the cutting path position is adjusted through compensation, ensuring the actual cutting trajectory meets processing requirements.

2. Drop out first (newly added in TubesT 7.1.57.19): This setting offers two cutting strategies for scallops:

-

-

-

Checked: Ensures definite drop-off.

-

Unchecked: Ensures parts are not damaged.

-

-

3. Apply to: You can apply Kerf Comp(fixed height) to the parts of the Current View, Part List, or Nest List.

Ⅳ. FAQS

1. How to cancel Kerf Compensate(fixed height)?

Click on the drop-down menu of Clear, and select Clear Kerf Comp(fixed height).

2. How the direction of Kerf Comp(fixed height) is determined?

The direction is determined automatically based on the position of wasted materials and the parts. However, if the direction is not what you prefer, you can send your feedback.

3. After setting the Kerf Comp(fixed height) parameters in TubesT, if it's found to be too large or too small during actual cutting, how to modify ?

It can be directly modified in FACut-H.

4. If ordinary compensation is set for parts with fixed height tool paths, whether it will take effect?

If the ordinary compensation is set for the part with a fixed-height toolpath, then the compensation will not be effective for the fixed-height toolpath. Namely, the fixed-height toolpath can only be set with the fixed-height compensation.