-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

I. Problem Description

When you open TubesT and import parts, pop-up prompts often appear:

II. Causes and Solutions

1. The part drawing is not a supported format:

Supported formats:

① IGS, SAT, and STEP formats exported from general 3D drawing software;

② T2T, X2T, IFC, and nc1 formats exported from Tekla software.

Note: The nc1 format only supports angle steel/channel steel/I-beam/rectangular tube sections.

Other software is currently not supported. These three programs are recommended.

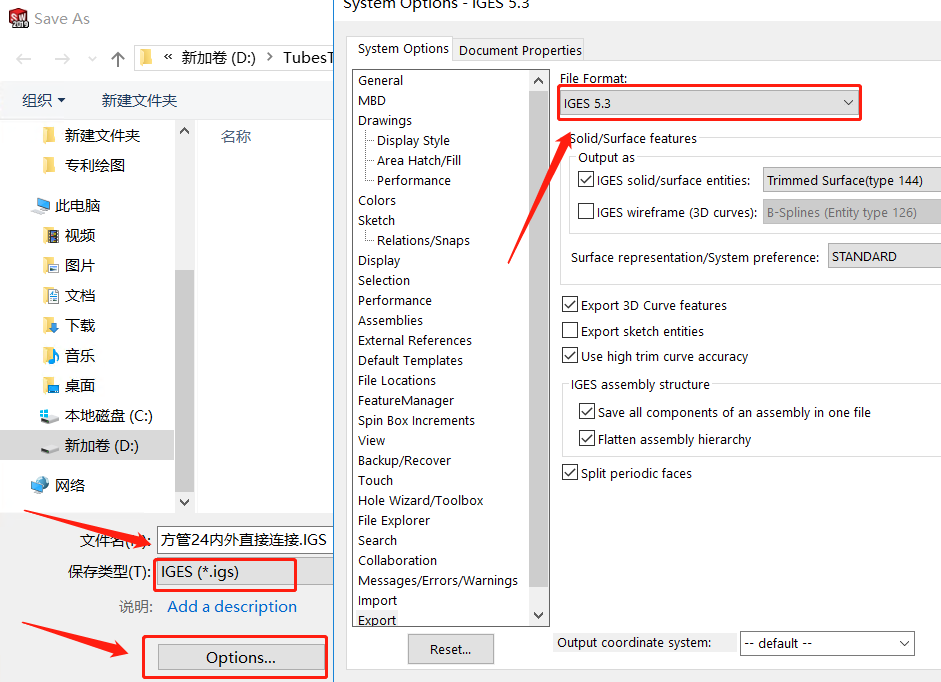

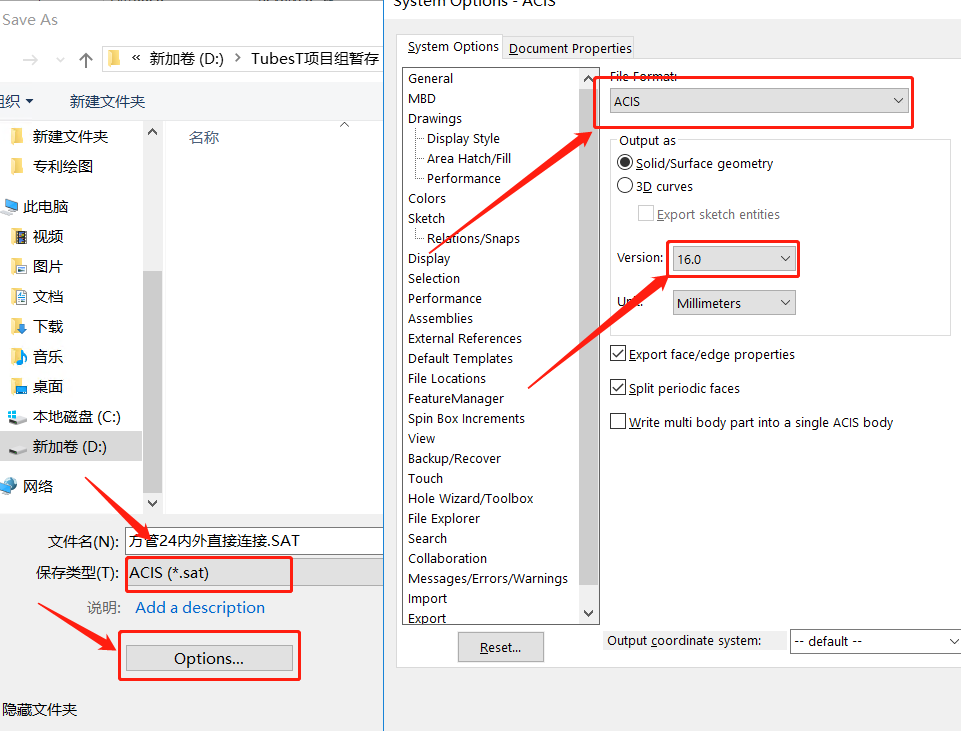

2. The export parameters of IGS or SAT files from external drawing software are not the recommended parameters:

(1) IGS suggested parameters

(2) SAT suggested parameters

If the SAT file saved in SolidWorks 2016 or later cannot be imported, set the ACIS version of the SAT file to 16.0–22.0.

3. Non-standard drawing specifications:

Examples: Sheet metal parts, non-standard L\C steel, I-beams, etc.

For specific methods of modifying the diagram and the legend, please see: 《 Common Part Modeling Specifications 》

4. Incorrect import parameter settings:

After selecting the drawing, a preview of the part and its cross-section information will appear on the right. "0.00x0.00x0.00" indicates that the drawing was not read. Clicking "Open" in this case will result in an import failure.

If the drawing itself is correct but still cannot be imported, the issue is likely due to incorrect import settings:

(1) Extrusion Direction:

"Auto" means automatic selection, where the software reads the extrusion direction from the file. If the automatically detected direction does not match the actual part, adjust it manually until the cross-section type and preview match the actual tube shape.

(2) L-Steel/C-Steel:

For sheet metal parts like angle steel, channel steel, or C-shaped steel, need to check the <L/C profile> option to generate special toolpaths.

(3) Nested Holes:

If the part contains "other parts on scrap material," check In-part shape during import; otherwise, the parts will separate after import. Do not check this for assemblies.

Notes:

① If the import failure persists after following the above steps, send the drawing file to the TubesT support group for analysis by our engineers.

② Simple parts (e.g., rectangular tubes) can be drawn directly in TubesT. Refer to tutorial: 《 TubesT - Draw Part 》 .

I. Problem Description

When you open TubesT and import parts, pop-up prompts often appear:

II. Causes and Solutions

1. The part drawing is not a supported format:

Supported formats:

① IGS, SAT, and STEP formats exported from general 3D drawing software;

② T2T, X2T, IFC, and nc1 formats exported from Tekla software.

Note: The nc1 format only supports angle steel/channel steel/I-beam/rectangular tube sections.

Other software is currently not supported. These three programs are recommended.

2. The export parameters of IGS or SAT files from external drawing software are not the recommended parameters:

(1) IGS suggested parameters

(2) SAT suggested parameters

If the SAT file saved in SolidWorks 2016 or later cannot be imported, set the ACIS version of the SAT file to 16.0–22.0.

3. Non-standard drawing specifications:

Examples: Sheet metal parts, non-standard L\C steel, I-beams, etc.

For specific methods of modifying the diagram and the legend, please see: 《 Common Part Modeling Specifications 》

4. Incorrect import parameter settings:

After selecting the drawing, a preview of the part and its cross-section information will appear on the right. "0.00x0.00x0.00" indicates that the drawing was not read. Clicking "Open" in this case will result in an import failure.

If the drawing itself is correct but still cannot be imported, the issue is likely due to incorrect import settings:

(1) Extrusion Direction:

"Auto" means automatic selection, where the software reads the extrusion direction from the file. If the automatically detected direction does not match the actual part, adjust it manually until the cross-section type and preview match the actual tube shape.

(2) L-Steel/C-Steel:

For sheet metal parts like angle steel, channel steel, or C-shaped steel, need to check the <L/C profile> option to generate special toolpaths.

(3) Nested Holes:

If the part contains "other parts on scrap material," check In-part shape during import; otherwise, the parts will separate after import. Do not check this for assemblies.

Notes:

① If the import failure persists after following the above steps, send the drawing file to the TubesT support group for analysis by our engineers.

② Simple parts (e.g., rectangular tubes) can be drawn directly in TubesT. Refer to tutorial: 《 TubesT - Draw Part 》 .