-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

I. How to Use

- Definition

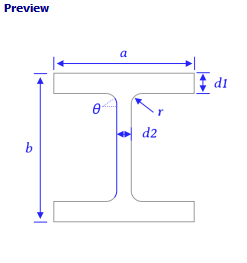

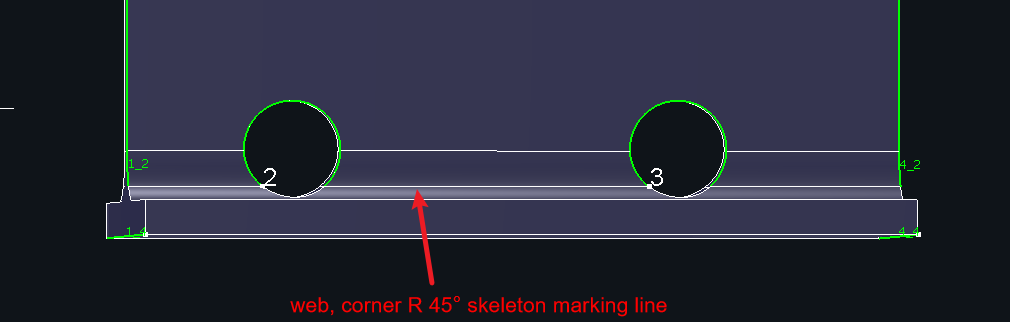

When drawing a H-beam, the section preview is shown below:

As you can see, on one side of the web, the starting and ending points of the corner R form a θ angle of 90° with the circle center.

-

-

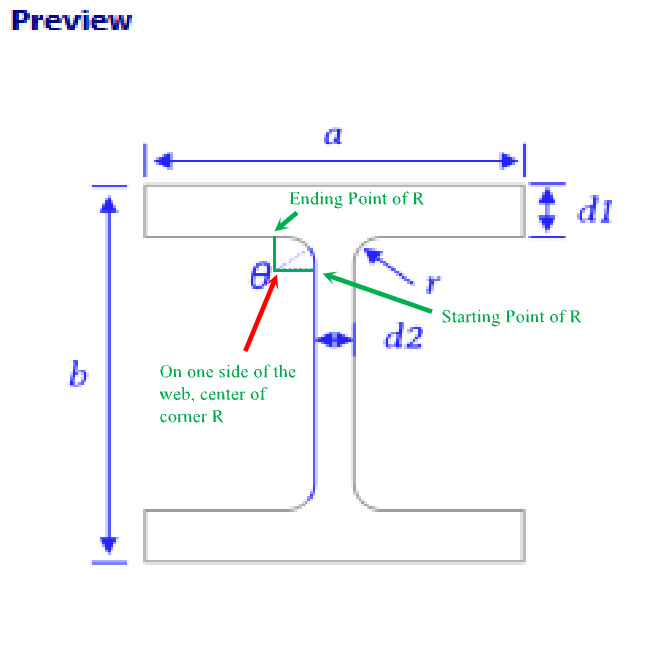

- The length of the web toolpath varies with different θ angles.

- Based on experience, if θ exceeds 45°, it may cause interference during cutting.

- The closer the web toolpath is to the flange, the easier it is to cut.

- By default, θ is set to 45°, meaning the farthest point of the web toolpath aligns with half of the corner R.

-

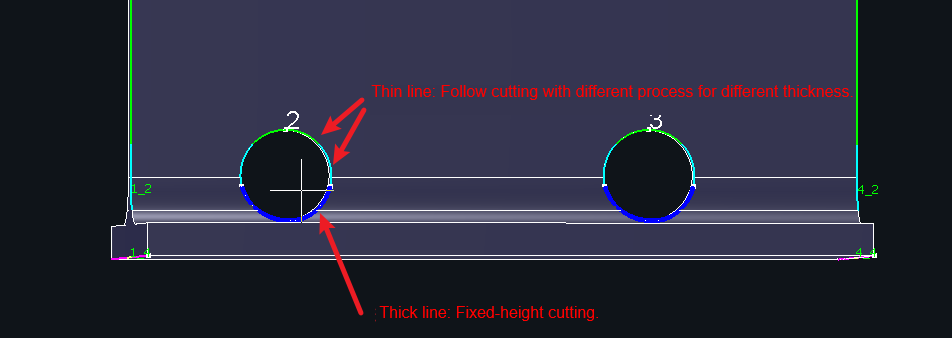

The image below illustrates the difference:

- Specific Operations

θ-related parameters are not available in the Draw Part. The web toolpath endpoint of drawn or imported parts is managed in:

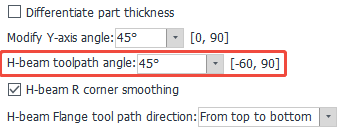

User Preference Settings → User Preference (scroll down to Other) → H-Beam toolpath angle.

-

-

- Default value: 45°. Modification is not recommended. If modified, it should not exceed 45° due to interference risks.

- Set the θ angle before importing parts—once imported, the option is grayed out.

-

If parts have already been imported, even deleting all parts does not restore access to this setting. You must click New in the top-left corner before adjusting the setting in the User Preference Settings.

-

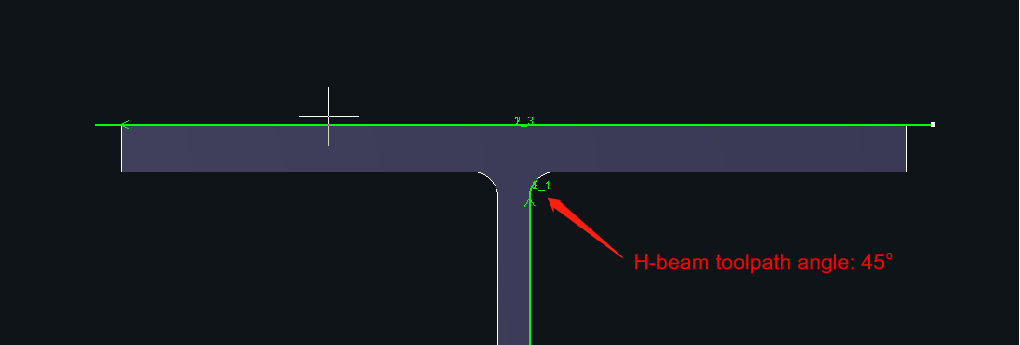

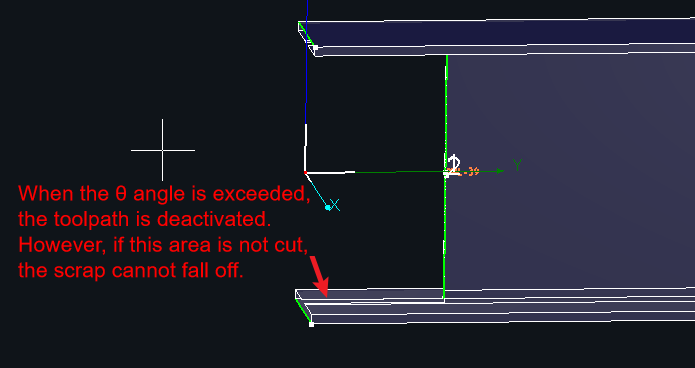

When θ exceeds the set limit, the system automatically whitens (not processed) that section of the toolpath to ensure safety. Here is a typical case.

II. Common Scenarios and Solutions

- Case 1

-

- For toolpaths where θ < 45°, the cutting head follows the path normally.

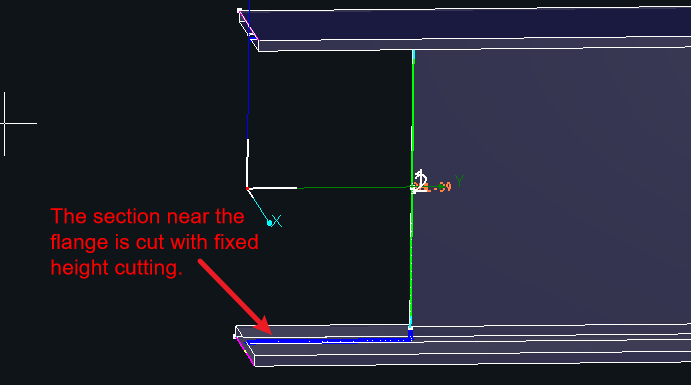

- For toolpaths where θ > 45°, the software disables the toolpath automatically. If you still want to process these areas, it is recommended to use Fixed height cutting.

Use the Optimize H-Beam Web Toolpath function to set this automatically.

Before Optimization:

After Optimization:

Before Optimization:

After Optimization:

- Case 2

If the R size of the I-beam does not match the drawing exactly, and you want to shorten the web toolpath at corner R to avoid collisions during cutting, you can reduce the θ angle slightly.

-

-

-

Modifying this value is generally not recommended unless necessary.

-

After making changes, reset the value to default before reopening the software to prevent unintended toolpath issues in future operations.

-

This setting applies to all parts, so ensure that all parts in a batch are compatible with the adjustment.

-

-

The values in the image are for reference only; adjust based on actual conditions.

I. How to Use

- Definition

When drawing a H-beam, the section preview is shown below:

As you can see, on one side of the web, the starting and ending points of the corner R form a θ angle of 90° with the circle center.

-

-

- The length of the web toolpath varies with different θ angles.

- Based on experience, if θ exceeds 45°, it may cause interference during cutting.

- The closer the web toolpath is to the flange, the easier it is to cut.

- By default, θ is set to 45°, meaning the farthest point of the web toolpath aligns with half of the corner R.

-

The image below illustrates the difference:

- Specific Operations

θ-related parameters are not available in the Draw Part. The web toolpath endpoint of drawn or imported parts is managed in:

User Preference Settings → User Preference (scroll down to Other) → H-Beam toolpath angle.

-

-

- Default value: 45°. Modification is not recommended. If modified, it should not exceed 45° due to interference risks.

- Set the θ angle before importing parts—once imported, the option is grayed out.

-

If parts have already been imported, even deleting all parts does not restore access to this setting. You must click New in the top-left corner before adjusting the setting in the User Preference Settings.

-

When θ exceeds the set limit, the system automatically whitens (not processed) that section of the toolpath to ensure safety. Here is a typical case.

II. Common Scenarios and Solutions

- Case 1

-

- For toolpaths where θ < 45°, the cutting head follows the path normally.

- For toolpaths where θ > 45°, the software disables the toolpath automatically. If you still want to process these areas, it is recommended to use Fixed height cutting.

Use the Optimize H-Beam Web Toolpath function to set this automatically.

Before Optimization:

After Optimization:

Before Optimization:

After Optimization:

- Case 2

If the R size of the I-beam does not match the drawing exactly, and you want to shorten the web toolpath at corner R to avoid collisions during cutting, you can reduce the θ angle slightly.

-

-

-

Modifying this value is generally not recommended unless necessary.

-

After making changes, reset the value to default before reopening the software to prevent unintended toolpath issues in future operations.

-

This setting applies to all parts, so ensure that all parts in a batch are compatible with the adjustment.

-

-

The values in the image are for reference only; adjust based on actual conditions.