- Products

Product

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

-

BOCHU New Product

-

BOCHU New Product

-

FSWELD2800

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

BOCHU New Product -

BOCHU New Product

-

- Online Store

- Support

- About BOCHU

- Software Download

- Manual

- Video

- Tutorial

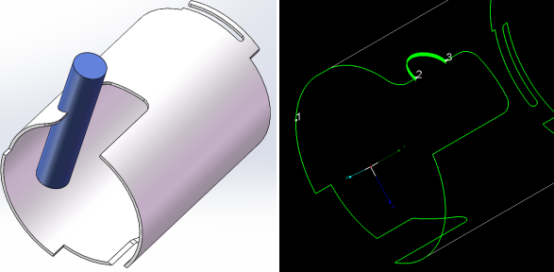

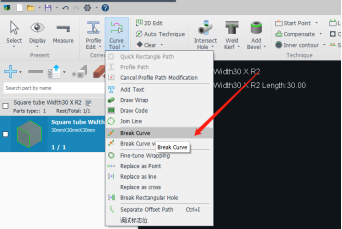

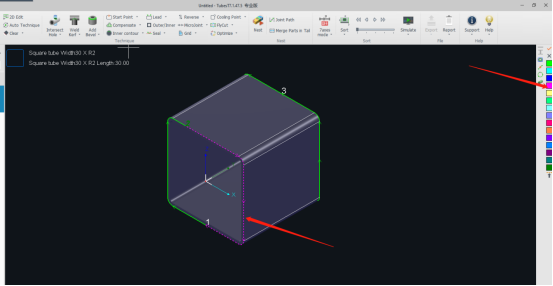

In the actual machining process, different processes may have to be used for the same figure in sections.

For example, in the figure below, the white round tube is the part to be machined. The circular section of the left cut-off line (section 2~3 in the figure) needs to be added with a coherent hole process, while the other parts are machined normally.

- Break Curve

- Select Specific Layer for the Broken Cutting Path

- Join the Line

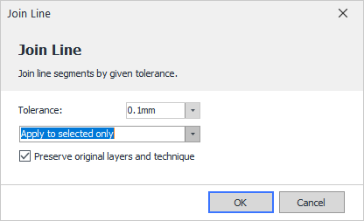

Since splitting a curve results in multiple perforation points in a complete section, the final merge is performed.

To join the broken lines, check <Preserve Original Layers and Technique>, which allows you to merge several segments of split curves into one, and keep each segment with a separately set toolpath (requires TubesT version not less than 1.23.4).

In the actual machining process, different processes may have to be used for the same figure in sections.

For example, in the figure below, the white round tube is the part to be machined. The circular section of the left cut-off line (section 2~3 in the figure) needs to be added with a coherent hole process, while the other parts are machined normally.

- Break Curve

- Select Specific Layer for the Broken Cutting Path

- Join the Line

Since splitting a curve results in multiple perforation points in a complete section, the final merge is performed.

To join the broken lines, check <Preserve Original Layers and Technique>, which allows you to merge several segments of split curves into one, and keep each segment with a separately set toolpath (requires TubesT version not less than 1.23.4).

-

Email subscription

-

Contact us

-

Downloads