How BOCHU Cutting Heads Transformed a Bulgarian Company’s Operations

In the fast-paced world of laser cutting, efficiency and cost management are critical for staying competitive. For a Bulgarian company specializing in laser cutting and processing, these challenges were a constant concern for its leader, Mr. Ivanov. Before adopting BOCHU cutting heads, Mr. Ivanov struggled with frequent equipment setbacks that disrupted production and strained resources. However, the introduction of BOCHU’s innovative technology marked a turning point, streamlining operations and boosting productivity.

The Challenge of Traditional Cutting Heads

Like many in the laser industry, Mr. Ivanov faced significant hurdles with conventional cutting heads. Collisions, an unavoidable risk in high-intensity cutting environments, often led to costly consequences. Each incident required sending the damaged cutting head back to the manufacturer for repairs, resulting in days of downtime, expensive maintenance fees, and substantial shipping costs. In urgent situations, Mr. Ivanov resorted to driving over 1,400 kilometers to personally deliver the cutting head for repairs, a process that left him physically and mentally exhausted. These disruptions not only delayed production but also eroded profitability, creating a cycle of frustration for the Bulgarian company.

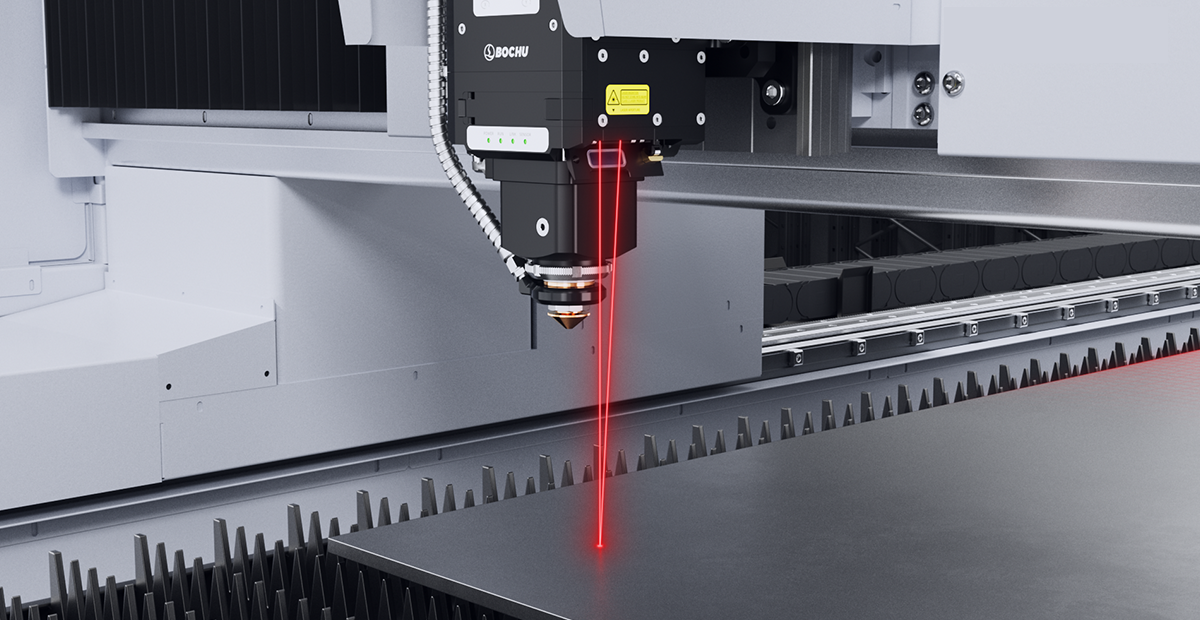

A Game-Changing Solution: BOCHU BLT6 Series Cutting Heads

The turning point came when Mr. Ivanov discovered the BOCHU BLT6 series cutting heads. Designed with ingenuity, these cutting heads feature a modular construction that splits the head into two distinct parts: the easily impacted nozzle and the main body housing the critical lenses. This innovative design incorporates a unique protective mechanism. In the event of a collision, four specially engineered screws connecting the two parts are designed to break first, allowing the nozzle to detach while leaving the main body virtually unscathed.

This breakthrough eliminates the need for extensive repairs or factory returns. Instead, Mr. Ivanov’s team can simply replace the screws and nozzle, following a few straightforward steps to resume production almost immediately. What once caused days of downtime and significant expense is now resolved in a matter of hours, if not minutes.

Transforming Operations and Boosting Efficiency

The adoption of BOCHU cutting heads has revolutionized the Bulgarian company’s operations. The ability to quickly address collisions has drastically reduced production interruptions, ensuring a smoother and more reliable workflow. The cost savings are equally significant—eliminating expensive repair fees and long-distance shipping has directly improved the company’s bottom line.

Mr. Ivanov, once burdened by the constant threat of equipment failure, now enjoys peace of mind. The BOCHU BLT6 series has not only solved a major operational challenge but also enhanced the company’s ability to meet tight deadlines and maintain high-quality output. This technological innovation has allowed the Bulgarian company to stay competitive in an increasingly demanding market.

A Partnership for the Future

BOCHU’s cutting-edge technology has created tangible value for the Bulgarian company, earning Mr. Ivanov’s trust and loyalty. By addressing the critical pain points of downtime and repair costs, BOCHU has empowered the company to focus on what it does best: delivering precision laser cutting services to its clients.

As the Bulgarian company looks to the future of laser technology, BOCHU remains a steadfast partner, providing innovative solutions and unwavering support. With BOCHU cutting heads, the company is well-equipped to navigate the challenges of the industry, ensuring continued growth and success in the ever-evolving world of laser cutting.