- Products

Product

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

BOCHU New Product

-

Portfolio

BOCHU New Product -

BOCHU New Product

-

FSWELD2800

BOCHU New Product -

Structural Steel Cutting Head

Plane Bevel Cutting Head

Tube Cutting Head

2D Cutting Head

BOCHU New Product -

BOCHU High-Speed Servo Drive

BOCHU New Product

-

- Online Store

- Service & Support

- About BOCHU

- Software Download

- Manual

- Tutorial

- CloudNest

Process Drawing Feature Update:

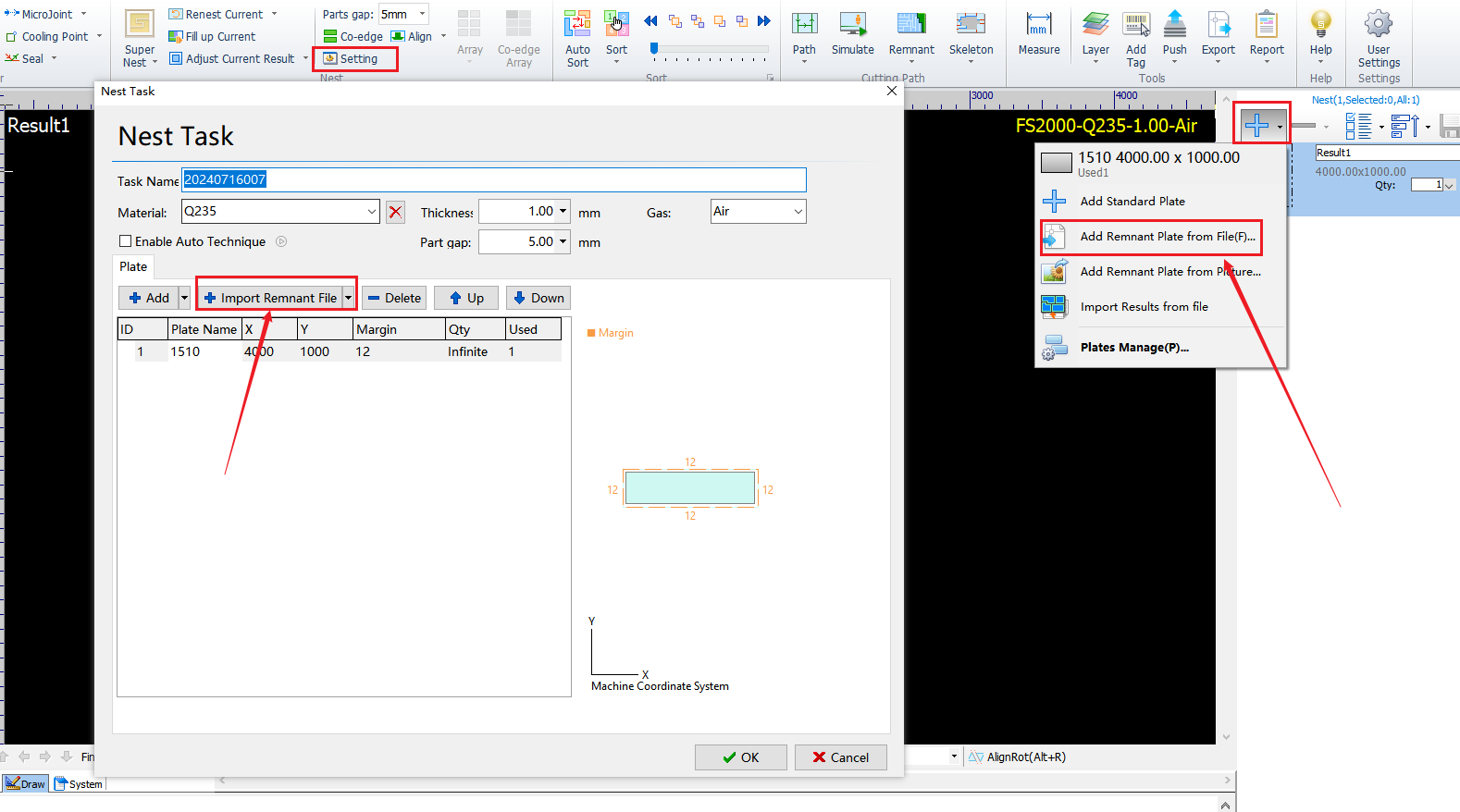

1.Import Remnant File supports importing CAD files containing multiple leftovers

Some users' CAD files contain multiple Remnant plate, and they need to manually separate these in order to import Remnant plate split into separate CAD files, and then imported into CypNest, which is quite troublesome. 2024V2 Version Import Remnant File supports importing CAD files containing multiple leftover images.

2.Supports batch setting of different layers based on contour size

Some users need different machining speeds when machining parts OuterContour and small bores because the outside Larger contours can be cut more quickly, while slower cutting is desired for inner holes to improve quality. Currently, CypNest can be manually selected to set different layers for contours inside Contour Size, but the operation is quite troublesome, so users hope to be able to set the size The software can automatically apply different layers to different Contour Size contours within the range.

In the new version, the Graph Replace module in the preprocessing interface adds Process type: [Do not replace], and Method of processing new add [Processing 2], so users can set different CutTech for large Small Contour in the software.

Report Feature Update:

1.Report supports horizontal display

Many users want a landscape Report template, because the layout thumbnail will be larger and more visible and when there are many parallel pieces of information, arranging them horizontally will be clearer. The 2024V2 version in the new version.The Report interface adds a checkbox for [Enable landscape report form], which can be modified when editing Personal, After checking, Report is displayed horizontally.

2.The new version has added the field [Perforation Amount] in Report ResultInfo

In the old version, the ResultInfo module of Report does not have Perforation Amount on each type of layout at PriceInfo ,What is counted is the Perforation Amount of all layouts, which is inconvenient for checking the perforation information of single sheets. So in 2024V2 ,in the new version, the ResultInfo module of version Report has added the field [Perforation Amount]. In ResultInfo New field, the field Select a value Perforation Amount, name the field as perforation or any other text, and click Save to use it.

Graphic Process Feature Update:

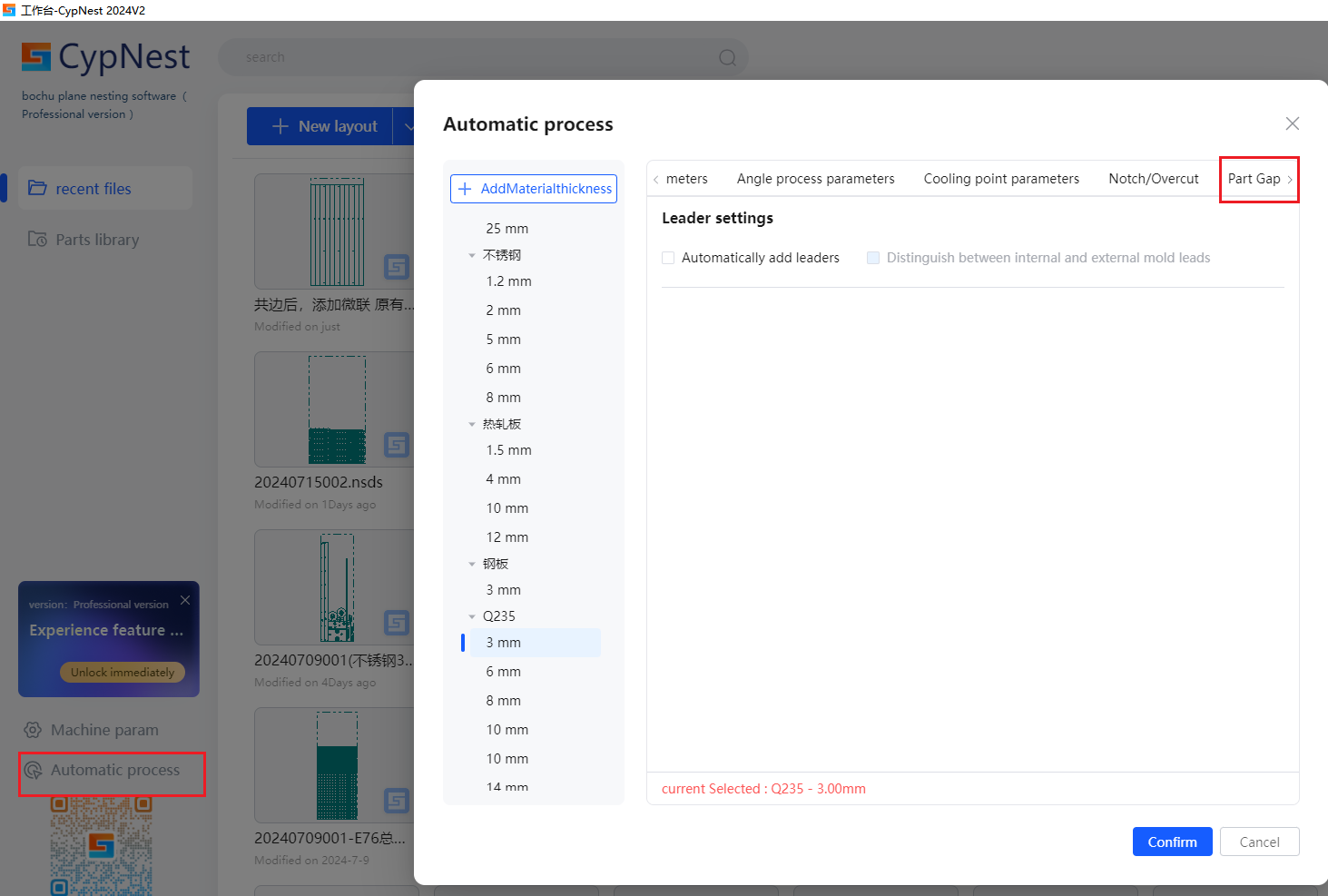

1.The automatic process interface of Open Multiple Textures supports setting Part Gap

Some users feedback that in the automatically generated Nest Task from CypNestOpen Multiple TexturesNest, Part Gap defaults to are all 1mm, and need to be manually modified each time, which is very troublesome. In the 2024V2 version, the automatic process configuration interface, adds a [Part Gap] column, so that the software can, after setting it, automatically assign according to tasks when using Open Multiple TexturesNest the material thickness gas automatically matches the corresponding Part Gap, no need to manually modify it anymore.

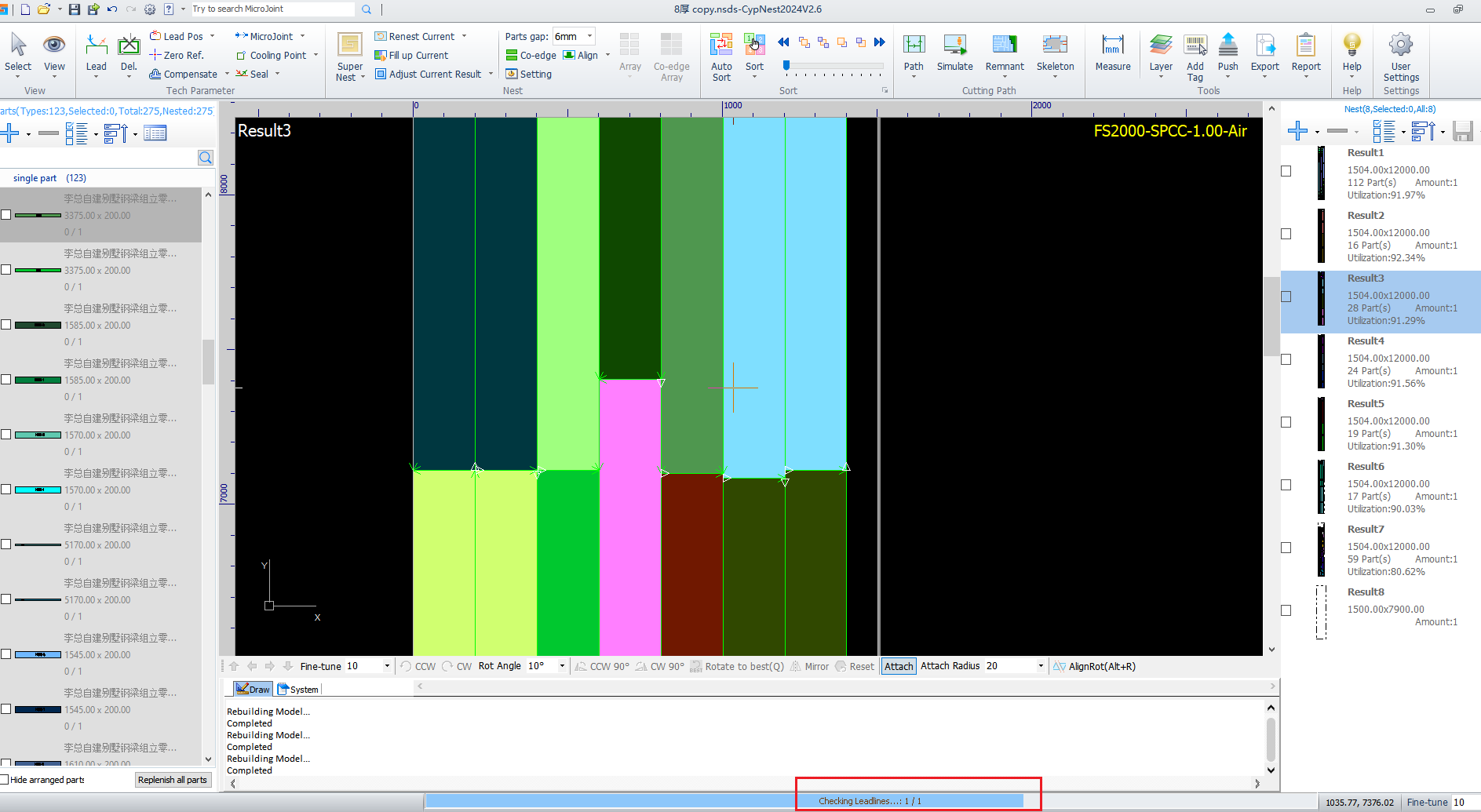

2.After supporting Manual Edit Toolpath, only check the lead wires of Current Result

In the old version, when double-clicking to adjust the Co-edge group, and clicking OK to return to the Nest main interface, the software will check .There are lead wires for the layout, but sometimes there are many Type of Result, and users just want to modify one layout Checking each of the Co-edge groups one by one is quite time-consuming. If users adjust each layout one by one, It's even more time-consuming. In version 2024V2, after exiting from Manual Edit Toolpath and returning to the main interface Nest, only Check the lead wires of Current Result.

CloudNest Feature Update:

1.CloudNest Cloud Report supports displaying leftover material lines

After the layout processing is completed, some users need to return Remnant plate to their customers, and the customers require the layout The leftover material lines should be displayed on the drawing. Previously, Cloud Reportresultsthumbnail did not display the leftover material lines, but the new version optimizes it resolved this issue.

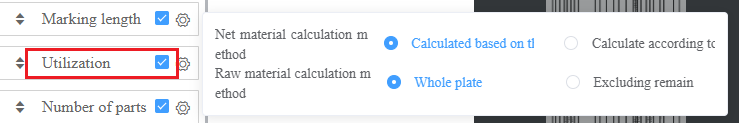

2.Cloud Report supports selecting the calculation method of Utilization

The old version's Cloud Report cannot Exclude Remnant to calculate the layout Utilization, and the new version has optimized this problem. Refer to the specific setting method in Report on how to change the calculation method of Utilization.

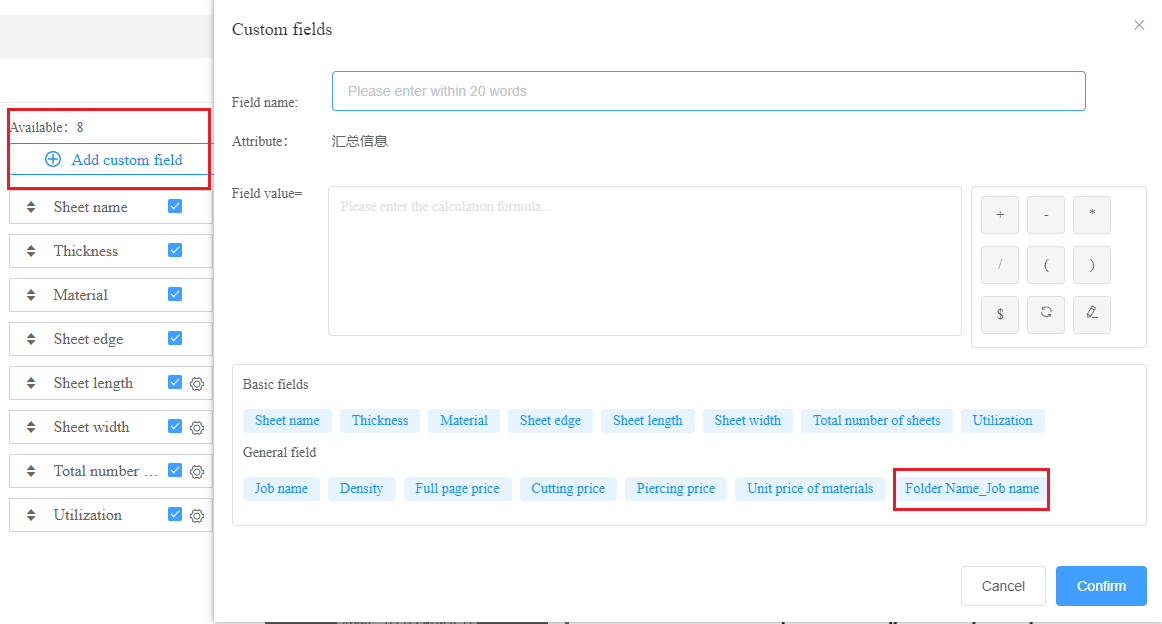

3.Cloud Report supports displaying the field [Folder Name - Job Name]

In actual Cutting, workshop operators may assign the layout to different machine tools for processing, corresponding with it. the Report will also be separated from this Report. When it is found that this layout does not correspond to the sheet or its .When he needs to modify the layout, he will take the separated page and give it to the layout technician for modification. Because Job name only shows on this Report of First page, making it difficult to find the corresponding job to modify this layout, so the new version has added the field [Folder Name - Job Name] in Cloud Report, which can be in Cloud Report Custom field.

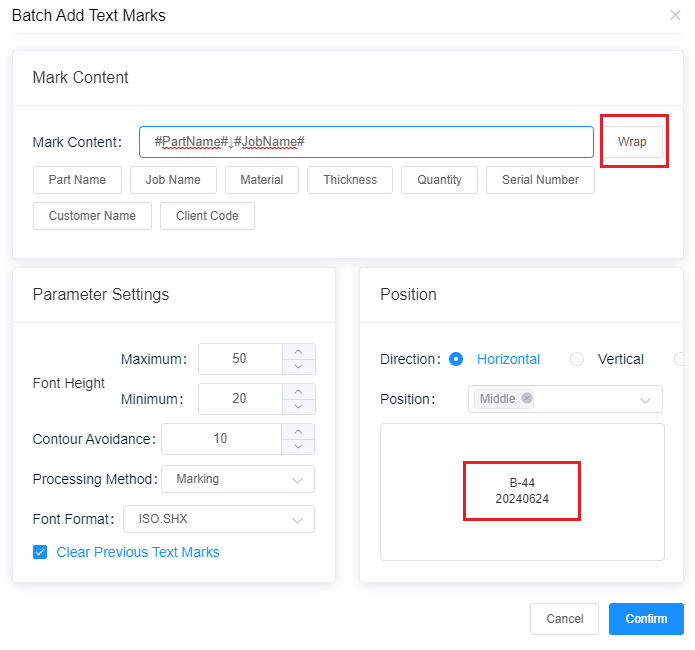

4.CloudNestPart ListText icon supports line break

Users have feedback that when adding marking information, all attribute information is displayed in one row, which is crowded and inconvenient to read. Especially in small parts, when all attribute information is displayed in one row, it may also cause information overload. Adding multiple failures. The new version has added when right-clicking Mark Batch Modification in the main interface of CloudNest. Line break function, effectively avoiding the above problems.

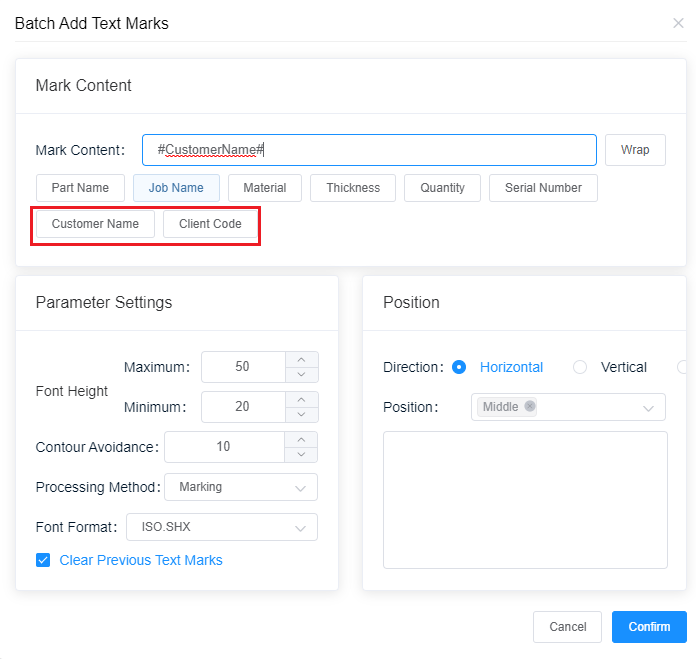

5.CloudNest batch Add label supports Add customer information

Some users may mix parts of different customers on one sheet during typesetting, maybe four or five customers' parts. when cutting, need a special warehouse manager to follow, measure one piece at a time, which is more troublesome. Therefore, hope to mark the customer's code on the parts for easy sorting. The new version has CloudNest in the parts column.The Mark Batch Modification interface has added two attributes [Customer Name] and [Client Code].

6.CloudNest supports batch setting of inner hole marking

In the steel structure industry, some thick plate parts need to be processed with flame cutting, while some inner holes are relatively small and need to be drilled. Machine processing of holes, the inner holes of these parts need to be marked, and then drilled after the parts OuterContour are cut. Hole machine processing inner hole. This can be achieved by batch setting marking for inner holes. Web CloudNest has added Part List. [Batch setting of inner hole marking] option. Refer to the specific setting method of batch setting of inner hole marking.

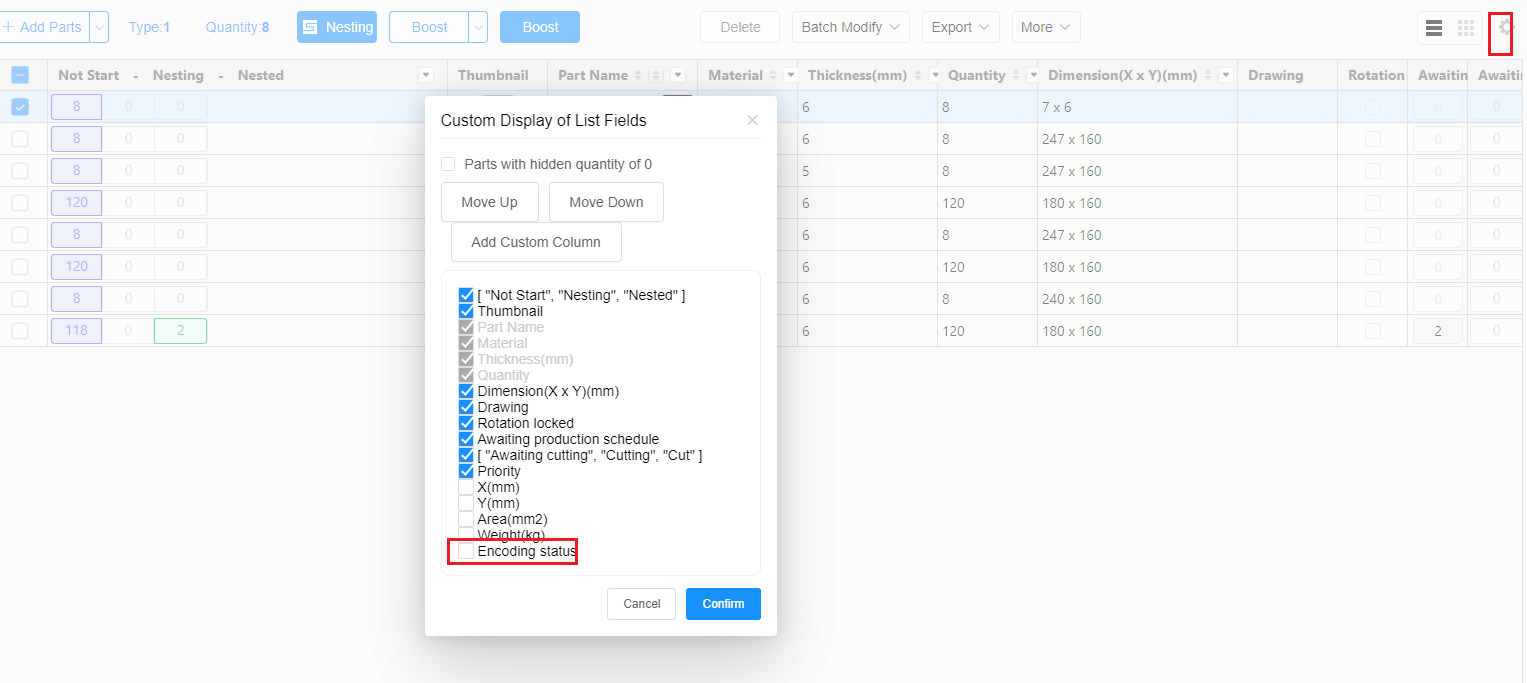

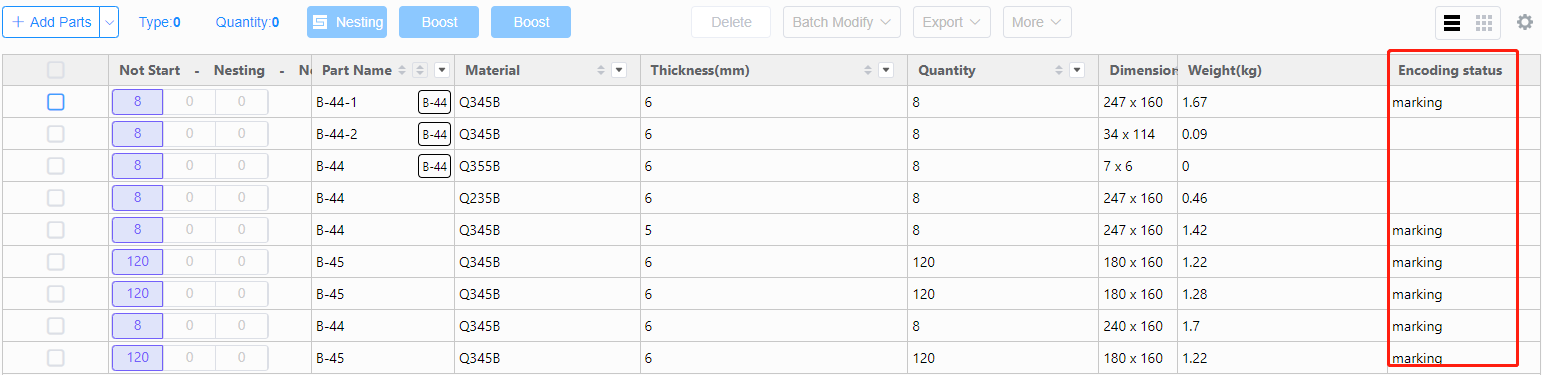

7.Web CloudNest supports displaying the coding status of parts

After the user added spray code information to the parts, it did not show up in Part List, resulting in an added. After adding, users don't know if it's added. Web Cloud Rank has added in Custom Column. [Coding status] check option, after checking, the parts with marking information and spray code information will be in Part List. It is reflected.

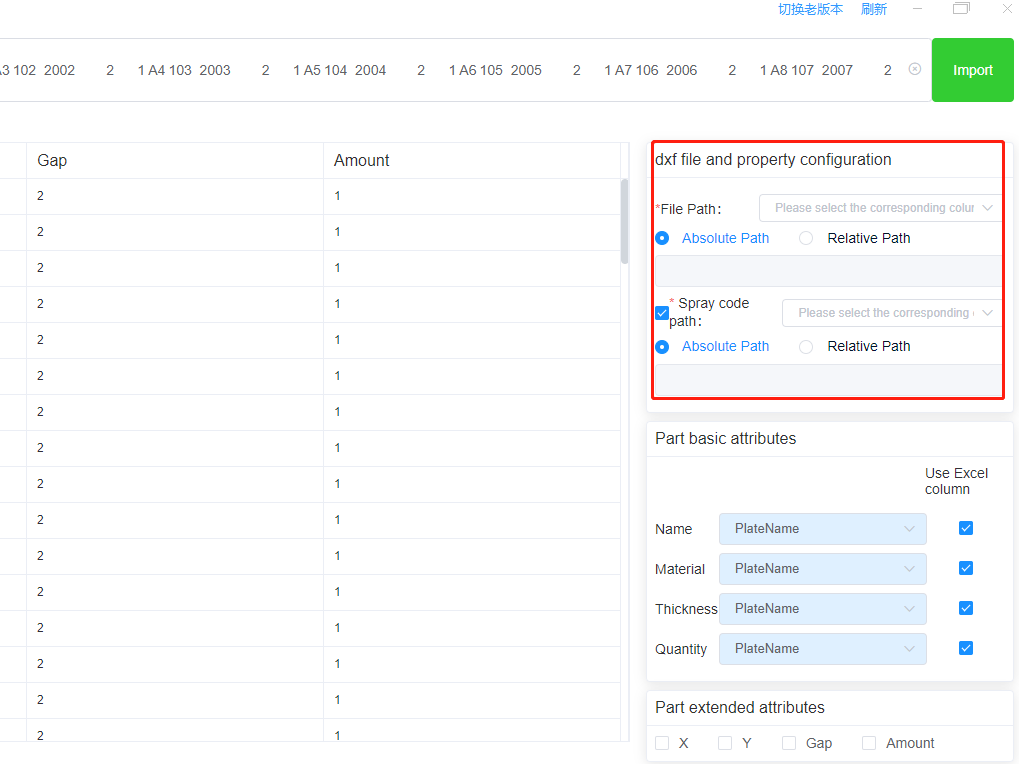

8.Web CloudNest supports Excel import of spray code images

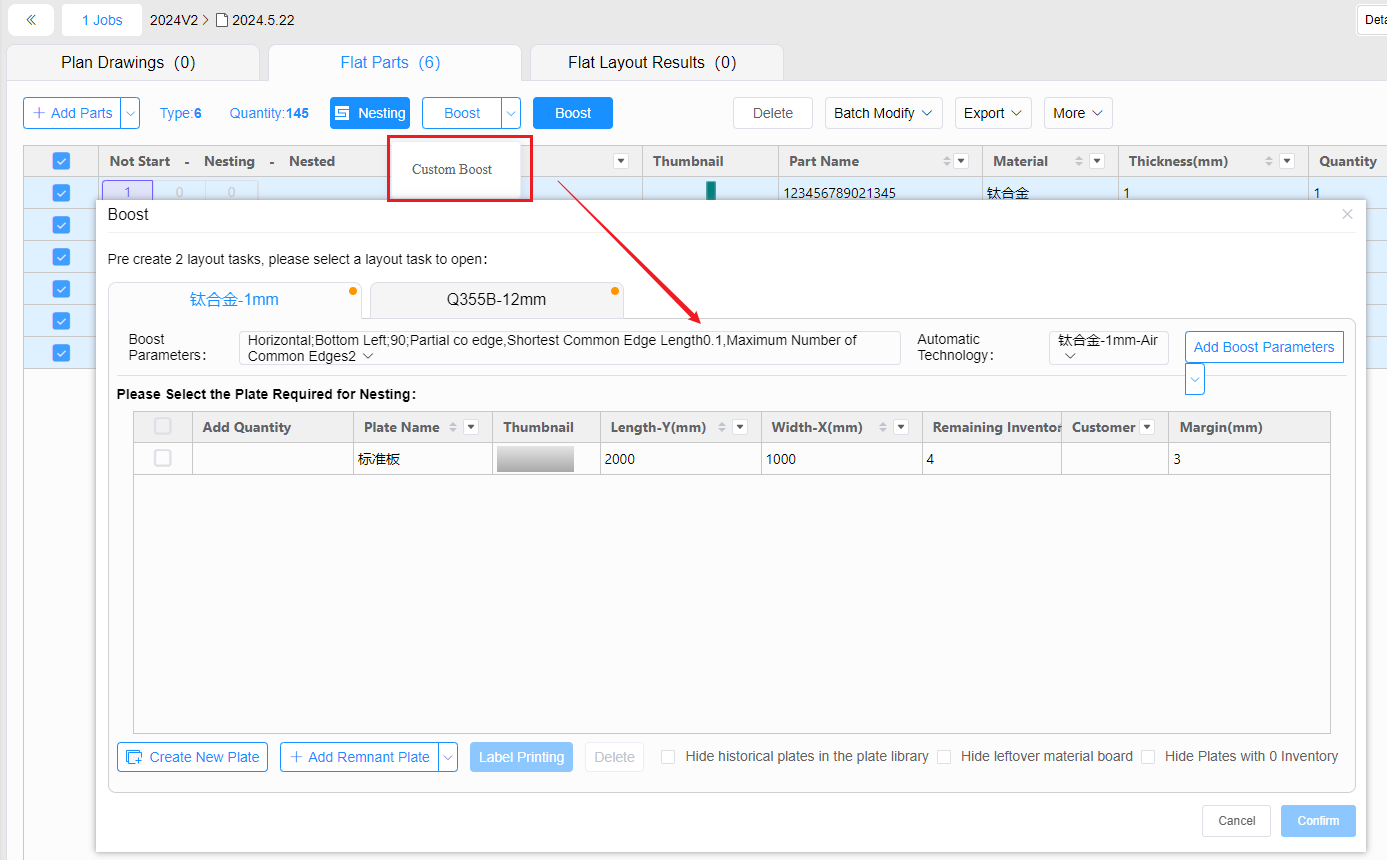

9.Web CloudNest supports Custom Boost parameters

The old version CloudNest was supported Custom Boost parameters when flying in Select Parts. Web Cloud Rank. It was not supported before, and the default was the first set of parameters in the setting-Boost Parameters, which can only be modified. It's very inconvenient to change this set of parameters to achieve the effect of replacing Boost Parameters.

The new version of Web CloudNest adds the option [Custom Boost] in the drop-down button for flying, supporting self. Define Boost Parameters. And in the setting-Boost Parameters, add the column of [parameter] in Param Preview without having to. It's more convenient to open and view.

Other feature updates:

1.New reinforcing font added

The software adds two kinds of reinforcing fonts, no need to manually bridge text, which can effectively save Process Drawing time.

Process Drawing Feature Update:

1.Import Remnant File supports importing CAD files containing multiple leftovers

Some users' CAD files contain multiple Remnant plate, and they need to manually separate these in order to import Remnant plate split into separate CAD files, and then imported into CypNest, which is quite troublesome. 2024V2 Version Import Remnant File supports importing CAD files containing multiple leftover images.

2.Supports batch setting of different layers based on contour size

Some users need different machining speeds when machining parts OuterContour and small bores because the outside Larger contours can be cut more quickly, while slower cutting is desired for inner holes to improve quality. Currently, CypNest can be manually selected to set different layers for contours inside Contour Size, but the operation is quite troublesome, so users hope to be able to set the size The software can automatically apply different layers to different Contour Size contours within the range.

In the new version, the Graph Replace module in the preprocessing interface adds Process type: [Do not replace], and Method of processing new add [Processing 2], so users can set different CutTech for large Small Contour in the software.

Report Feature Update:

1.Report supports horizontal display

Many users want a landscape Report template, because the layout thumbnail will be larger and more visible and when there are many parallel pieces of information, arranging them horizontally will be clearer. The 2024V2 version in the new version.The Report interface adds a checkbox for [Enable landscape report form], which can be modified when editing Personal, After checking, Report is displayed horizontally.

2.The new version has added the field [Perforation Amount] in Report ResultInfo

In the old version, the ResultInfo module of Report does not have Perforation Amount on each type of layout at PriceInfo ,What is counted is the Perforation Amount of all layouts, which is inconvenient for checking the perforation information of single sheets. So in 2024V2 ,in the new version, the ResultInfo module of version Report has added the field [Perforation Amount]. In ResultInfo New field, the field Select a value Perforation Amount, name the field as perforation or any other text, and click Save to use it.

Graphic Process Feature Update:

1.The automatic process interface of Open Multiple Textures supports setting Part Gap

Some users feedback that in the automatically generated Nest Task from CypNestOpen Multiple TexturesNest, Part Gap defaults to are all 1mm, and need to be manually modified each time, which is very troublesome. In the 2024V2 version, the automatic process configuration interface, adds a [Part Gap] column, so that the software can, after setting it, automatically assign according to tasks when using Open Multiple TexturesNest the material thickness gas automatically matches the corresponding Part Gap, no need to manually modify it anymore.

2.After supporting Manual Edit Toolpath, only check the lead wires of Current Result

In the old version, when double-clicking to adjust the Co-edge group, and clicking OK to return to the Nest main interface, the software will check .There are lead wires for the layout, but sometimes there are many Type of Result, and users just want to modify one layout Checking each of the Co-edge groups one by one is quite time-consuming. If users adjust each layout one by one, It's even more time-consuming. In version 2024V2, after exiting from Manual Edit Toolpath and returning to the main interface Nest, only Check the lead wires of Current Result.

CloudNest Feature Update:

1.CloudNest Cloud Report supports displaying leftover material lines

After the layout processing is completed, some users need to return Remnant plate to their customers, and the customers require the layout The leftover material lines should be displayed on the drawing. Previously, Cloud Reportresultsthumbnail did not display the leftover material lines, but the new version optimizes it resolved this issue.

2.Cloud Report supports selecting the calculation method of Utilization

The old version's Cloud Report cannot Exclude Remnant to calculate the layout Utilization, and the new version has optimized this problem. Refer to the specific setting method in Report on how to change the calculation method of Utilization.

3.Cloud Report supports displaying the field [Folder Name - Job Name]

In actual Cutting, workshop operators may assign the layout to different machine tools for processing, corresponding with it. the Report will also be separated from this Report. When it is found that this layout does not correspond to the sheet or its .When he needs to modify the layout, he will take the separated page and give it to the layout technician for modification. Because Job name only shows on this Report of First page, making it difficult to find the corresponding job to modify this layout, so the new version has added the field [Folder Name - Job Name] in Cloud Report, which can be in Cloud Report Custom field.

4.CloudNestPart ListText icon supports line break

Users have feedback that when adding marking information, all attribute information is displayed in one row, which is crowded and inconvenient to read. Especially in small parts, when all attribute information is displayed in one row, it may also cause information overload. Adding multiple failures. The new version has added when right-clicking Mark Batch Modification in the main interface of CloudNest. Line break function, effectively avoiding the above problems.

5.CloudNest batch Add label supports Add customer information

Some users may mix parts of different customers on one sheet during typesetting, maybe four or five customers' parts. when cutting, need a special warehouse manager to follow, measure one piece at a time, which is more troublesome. Therefore, hope to mark the customer's code on the parts for easy sorting. The new version has CloudNest in the parts column.The Mark Batch Modification interface has added two attributes [Customer Name] and [Client Code].

6.CloudNest supports batch setting of inner hole marking

In the steel structure industry, some thick plate parts need to be processed with flame cutting, while some inner holes are relatively small and need to be drilled. Machine processing of holes, the inner holes of these parts need to be marked, and then drilled after the parts OuterContour are cut. Hole machine processing inner hole. This can be achieved by batch setting marking for inner holes. Web CloudNest has added Part List. [Batch setting of inner hole marking] option. Refer to the specific setting method of batch setting of inner hole marking.

7.Web CloudNest supports displaying the coding status of parts

After the user added spray code information to the parts, it did not show up in Part List, resulting in an added. After adding, users don't know if it's added. Web Cloud Rank has added in Custom Column. [Coding status] check option, after checking, the parts with marking information and spray code information will be in Part List. It is reflected.

8.Web CloudNest supports Excel import of spray code images

9.Web CloudNest supports Custom Boost parameters

The old version CloudNest was supported Custom Boost parameters when flying in Select Parts. Web Cloud Rank. It was not supported before, and the default was the first set of parameters in the setting-Boost Parameters, which can only be modified. It's very inconvenient to change this set of parameters to achieve the effect of replacing Boost Parameters.

The new version of Web CloudNest adds the option [Custom Boost] in the drop-down button for flying, supporting self. Define Boost Parameters. And in the setting-Boost Parameters, add the column of [parameter] in Param Preview without having to. It's more convenient to open and view.

Other feature updates:

1.New reinforcing font added

The software adds two kinds of reinforcing fonts, no need to manually bridge text, which can effectively save Process Drawing time.

-

Email subscription

-

Contact us

-

Download