- Products

Product

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

BOCHU New Product

-

Portfolio

BOCHU New Product -

BOCHU New Product

-

FSWELD2800

BOCHU New Product -

Structural Steel Cutting Head

Plane Bevel Cutting Head

Tube Cutting Head

2D Cutting Head

BOCHU New Product -

BOCHU High-Speed Servo Drive

BOCHU New Product

-

- Online Store

- Service & Support

- About BOCHU

- Software Download

- Manual

- Video

- Tutorial

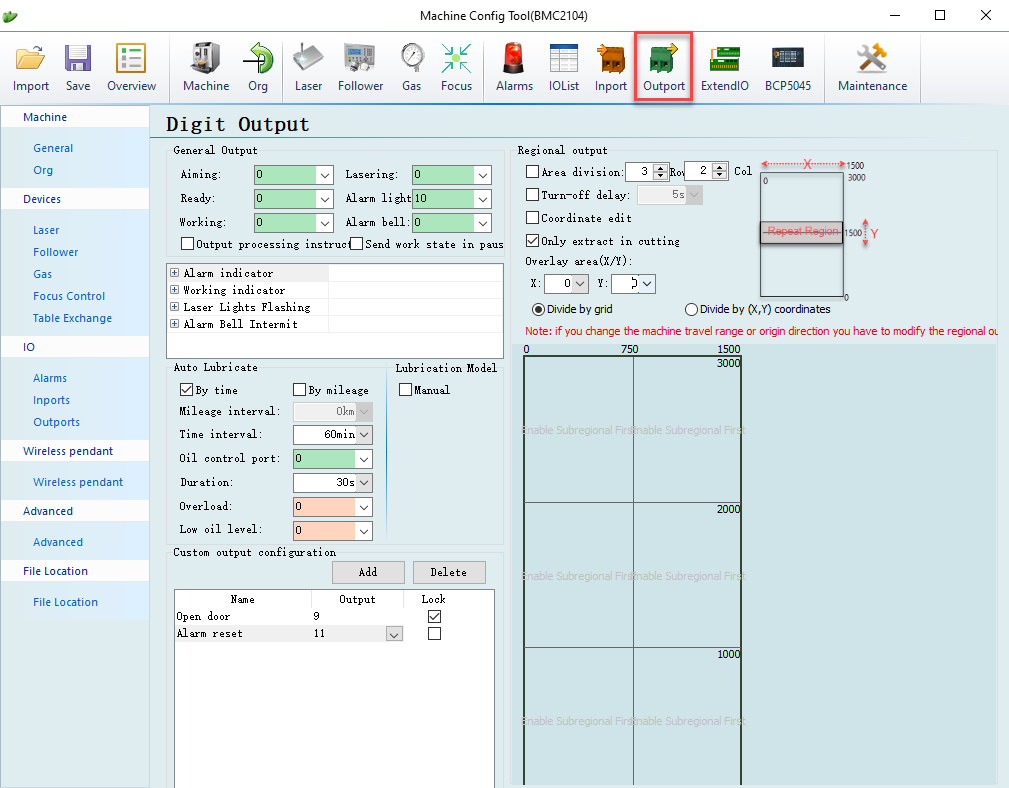

Output Config

To config the output needed, one I/O port can only be assigned once. You can check all assigned input and output in IO list. Related function setup in this page are:

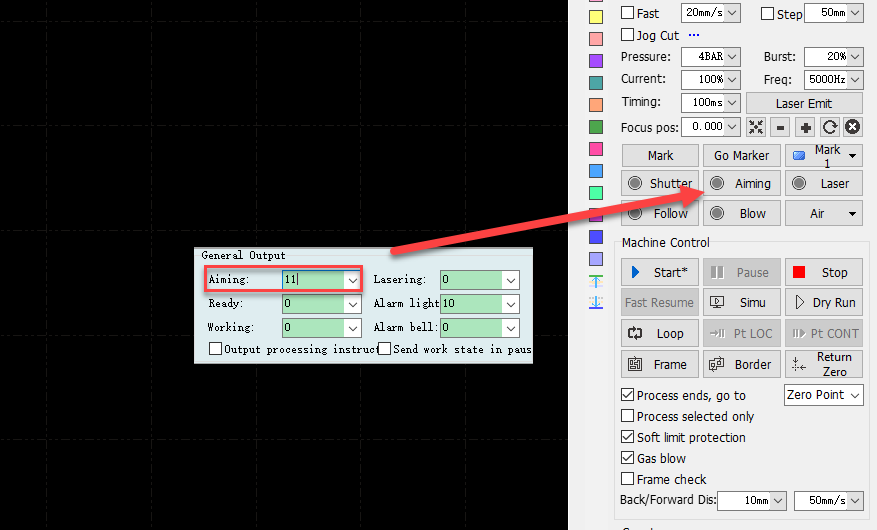

Aiming Laser

Assign the guide/pilot laser output to the aiming port. It works for  button on control panel.

button on control panel.

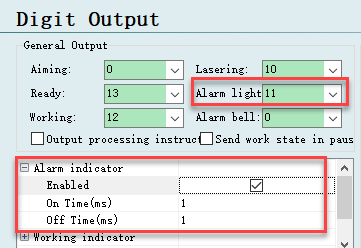

3-Color Indicator Lamp and Alarm Bell

Assign the output, then set lamp turn on/off interval to realize indicator flashing effect. Below is alarm indicator as an example, when system in alarm status will activate alarm lamp.

Other lamp configuration are same with alarm lamp.

Lasering: system will activate the output when laser emitting;

Ready: system will activate the output when there is no alarm and system is in idle status;

Working: system will activate the output when machine in working status.

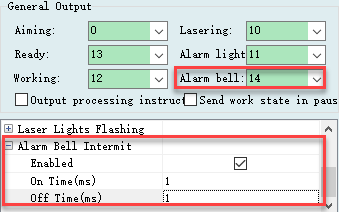

Alarm Bell

Alarm bell is same logic with 3-color indicator. Assign an output for alarm bell control then setup time interval to realize bell buzzing effect.

Dust Extractor

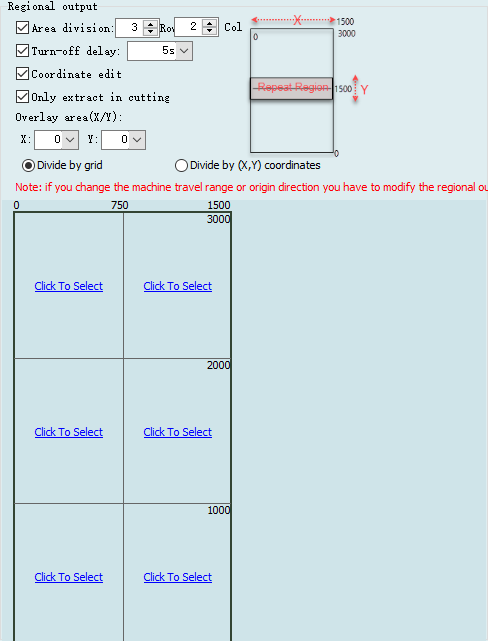

Assign the control output of dust extractor for different cleaning zone, once laser head works into specified area, the dust collector in this area will be activated by CypCut.

Auto Lubrication

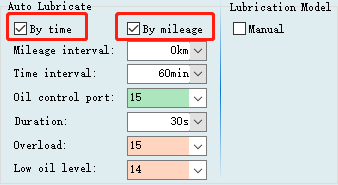

System can control oil pump to execute mechanism lubrication automatically by a time period or by a running length. You can also set external input signal for oil pump alarm detection.

'By time' is to execute lubrication by preset time interval, and 'By mileage' is to execute lubrication by given machine running length, you can select one of the options or both. You can

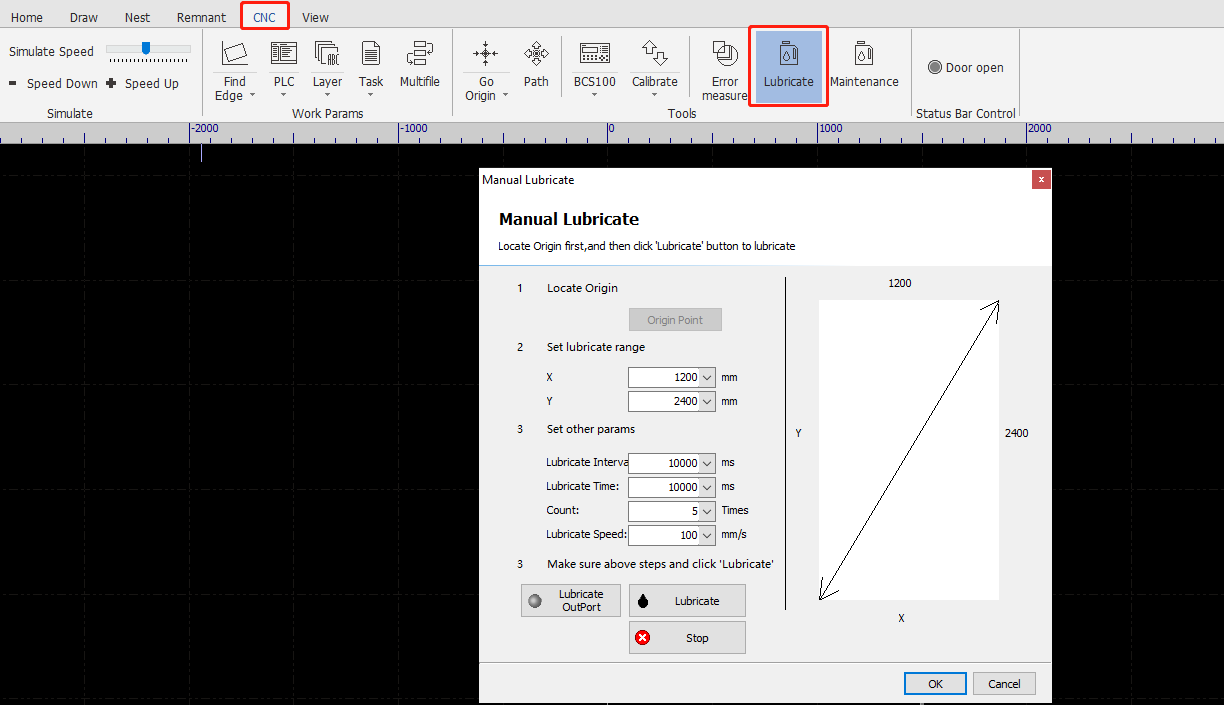

also enable  option so there will be a 'Lubrication' option displayed on CypCut > CNC tab > Tools group, which allow user to set speed and path of lubrication.

option so there will be a 'Lubrication' option displayed on CypCut > CNC tab > Tools group, which allow user to set speed and path of lubrication.

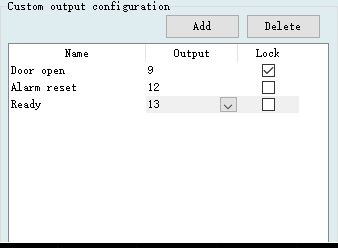

Custom Output

You can assign an output for needed function control.

Output Config

To config the output needed, one I/O port can only be assigned once. You can check all assigned input and output in IO list. Related function setup in this page are:

Aiming Laser

Assign the guide/pilot laser output to the aiming port. It works for  button on control panel.

button on control panel.

3-Color Indicator Lamp and Alarm Bell

Assign the output, then set lamp turn on/off interval to realize indicator flashing effect. Below is alarm indicator as an example, when system in alarm status will activate alarm lamp.

Other lamp configuration are same with alarm lamp.

Lasering: system will activate the output when laser emitting;

Ready: system will activate the output when there is no alarm and system is in idle status;

Working: system will activate the output when machine in working status.

Alarm Bell

Alarm bell is same logic with 3-color indicator. Assign an output for alarm bell control then setup time interval to realize bell buzzing effect.

Dust Extractor

Assign the control output of dust extractor for different cleaning zone, once laser head works into specified area, the dust collector in this area will be activated by CypCut.

Auto Lubrication

System can control oil pump to execute mechanism lubrication automatically by a time period or by a running length. You can also set external input signal for oil pump alarm detection.

'By time' is to execute lubrication by preset time interval, and 'By mileage' is to execute lubrication by given machine running length, you can select one of the options or both. You can

also enable  option so there will be a 'Lubrication' option displayed on CypCut > CNC tab > Tools group, which allow user to set speed and path of lubrication.

option so there will be a 'Lubrication' option displayed on CypCut > CNC tab > Tools group, which allow user to set speed and path of lubrication.

Custom Output

You can assign an output for needed function control.

-

Email subscription

-

Contact us

-

Download