- Products

Product

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

BOCHU New Product

-

Portfolio

BOCHU New Product -

BOCHU New Product

-

FSWELD2800

BOCHU New Product -

Structural Steel Cutting Head

Plane Bevel Cutting Head

Tube Cutting Head

2D Cutting Head

BOCHU New Product -

BOCHU High-Speed Servo Drive

BOCHU New Product

-

- Online Store

- Service & Support

- About BOCHU

- Technical Data

- Hardware

- Software

- Manual

FSCUT6000 High Power EtherCAT is a cost-effective EtherCAT bus laser cutting control system. Easy installation and debugging, excellent performance, and inclusive solutions for cutting medium thick plates for steel structures, iron towers, ships, etc. Functions like Smooth MicroJoint, Flash Piercing, and 5-Stage Piercing, can improve processing efficiency; Functions like Deslag and Corner Technique, can improve the quality of processing thick plates.

Technical Data

Control Software

CypCutPro Laser Cutting System

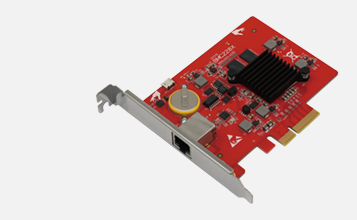

Control Card

BMC228B

Interface

PCIe bus, X4 and up

I/O terminal board

HPL2720E

Power supply

24V DC/3.5A

Motor control signal

EtherCAT Servo

Dedicated output

4 DA outputs: 0~10V, 12bit, ±20mV

1 PWM output: 24V, precision of 5KHz (0.3%)

Common input

27 common inputs

Active low, <15.6V

IN1~IN3 can change to active high, > 5.8V

Common output

20 common outputs

Max load per channel: DC 24V/700mA

Work environment

Temperature: 0~60℃

Humidity: 10%~90%RH(no condensation)

Benefits

Technique

Smooth MicroJoint: smooth cross section at MicroJoints for easy unloading and efficient production.

Fast Piercing: extremely fast piercing for high efficiency of piercing thin plate.

Deslag: remove slags after piercing and improve the piercing quality of thick plates.

5-Stage Piercing: piercing for even thicker plates.

Flash Piercing: fast frequency conversion piercing to improve the efficiency of piercing thick plates.

Corner Technique: improve the processing quality of the corner of a part.

Circle Centering: quickly locate the center of a circular plate to improve the processing efficiency.

One-Path FlyCut: cut any graphics without lifting the cutter to zero reference for a faster cutting speed.

Quick CutOff: cut off the plate along the X or Y direction with one click.

Vertex Marking: mark the bounding box of graphics to be cut for a clear processing range.

Frame Border Contour: ensure parts on non-rectangular plates are within the plates for safe production.

Built-in Nesting: free and easy nesting for higher plate utilization.

Control

Real-time EtherCat: easy to extend.

Virtual Multi-Station: set multiple stations on one machine tool to improve processing efficiency.

Side Anti-Collision: lift the cutter again, if a side object is detected during traveling , so side collision to the cutter is prevented.

FrogLeap Skip: smart adjust the height of the cutter during traveling to prevent the collision with tilted parts.

Protective FindEdge: protect the cutter from hitting the rack during edge finding.

Torque Monitor: monitor the servo torque, and stop immediately when it hits a heavy object to ensure both the machine tool and the operator safe.

Fast Import: scan QR code to import drawings, which is fast and accurate.

Coil machining: machining on coils to improve cutting efficiency.

InkJet Printer: print codes to mark parts quickly without damages.

Nozzle Cleaning: auto clean the nozzle to extend the nozzle life and improve machining quality.

Torque check: monitor the dual drive shaft state to avoid torsion.

Flexible Acceleration: flexible acceleration and deceleration for a longer machine tool life.

Motion

Theoretical control accuracy 0.005mm, practical trajectory accuracy 0.01mm, position accuracy 0.001mm, repetitive position accuracy 0.002mm.

Unlimited maximum travel speed and maximum machining speed.

Maximum acceleration 2G.

Application

For high-power fiber laser cutting machines of 6kW~12kW, widely used in ships, iron towers, steel structures and other industries.

Components

BMC228B

master card bmc228a

Number:1

HPL2720E

EtherCAT terminal board

Number:1

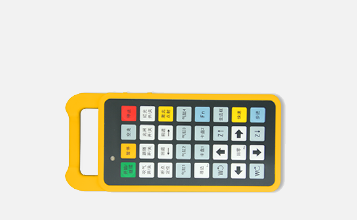

WKB

Wireless hand-held remote

Number:1

BCS210E

Height controller

Number:1

CypCutPro

CypCutPro

CypCutPro is mainly used for medium and high power EtherCAT cutting systems, and has simple operation and rich functions. Functions such as "five-stage piercing", "flash piercing", "deslag piercing", "corner technique", "smooth micro joint" and "smooth piercing" improve medium and thick plate processing quality and processing efficiency.

×

-

Email subscription

-

Contact us

-

Download