- Products

Product

-

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

BLT Intelligent Cutting

-

Industrial Automation

-

Industrial Software

-

BOCHU New Product

-

Portfolio

BOCHU New Product -

BOCHU New Product

-

FSWELD2800

BOCHU New Product -

Structural Steel Cutting Head

Plane Bevel Cutting Head

Tube Cutting Head

2D Cutting Head

BOCHU New Product -

BOCHU High-Speed Servo Drive

BOCHU New Product

-

- Online Store

- Service & Support

- About BOCHU

- Introduction

- Parameter

- Tutorial

- Manual

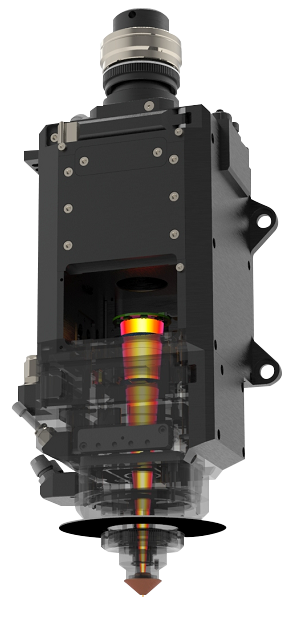

BLT 6 Series smart cutters are especially developed for ultra-high power laser equipment (max of 40kw). Brand new beam path design and optimized optical lens bring you great performance with stable cutting, simple installation and setup, and double dust prevention. The Smart Piercing and Auto Recut features, meeting the highly demanding standard of air as well as N2 high-power cutting, considerably improve efficiency and yield.

Stable and Efficient Cutting

Auto Recut

Real-time in-head sensor realizes stable cutting performance by detecting paths not cut through to give an automatic recut.

Smart Piercing

Real-time monitoring of piercing process make it possible to start cutting right after piercing. No more waiting, efficiency significantly improved.

Slag-free Cutting

Monitor the laser beam to timely turn it off to realize a slag-free cutting with no gap.

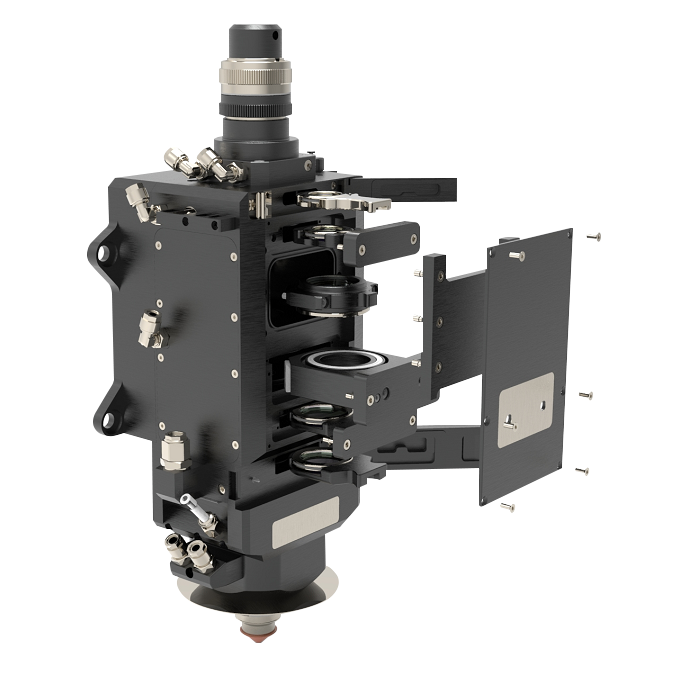

Easy to Maintain

Low Cost to Repair

Ready-to-use optics drawer, lens changed in 5 mins.

Protective screws keep cutting head from damage.

No time wasting on Depot Repair.

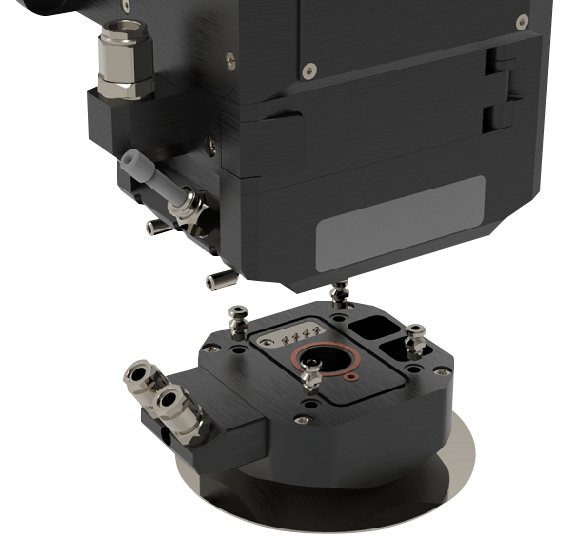

Smart and Safe Processing

Spring Energized Seal Test

Monitor the gas pressure of the first and second lower protective lens to give early warning.

Protective Lens Monitor

Upgraded algorithm integrated with sensor, effectively prevents protective lens from cracks caused by pollution.

Features

Auto Recut

Smart Piercing

Slag-free Cutting

Co-edged Smart Piercing

Maintenance

Upper Protective Lens Changing

Lower Protective Lens Changing

Protective Screws Changing

QD Connector Locking

| Cutter Model | BLT642H | BLT662H | BLT682H | BLT6102H |

| Power Level | ≤15kW | ≤20kW | ≤30kW | ≤40kW |

| Fiber Interface | Q+、QD、QBH、ADD | |||

| Focal Distance (mm) | 200 | 200 | 200/300 | 300 |

| Size (mm) | 428.3x181 | 498x181 | ||

| Weight(kg) | 约9.5 | 约12.5 | ||

| Auto Focus Range(mm) | ±50 | |||

| Laser Wavelength(nm) | 1030-1090 | |||

| Max Gas Pressure(Bar) | 25 | |||

| BLT 6 series Smart Cutter Feature | ||||

| Auto Recut | Protective Screws | Temperature Monitor Sensor | Cavity Temperature Monitor | Focusing Test |

| Smart Piercing | Focus Lens Monitor | Nozzle Cooling | Cavity Humidity Monitor | Spring Energized Seal Test |

| Co-edged Smart Piercing | Protective Lens Monitor | Water Cooling Sensor | Cavity Gas Pressure Monitor | Gas Pressure Monitor |

-

Email subscription

-

Contact us

-

Download